Equipment in PI's Laboratory:

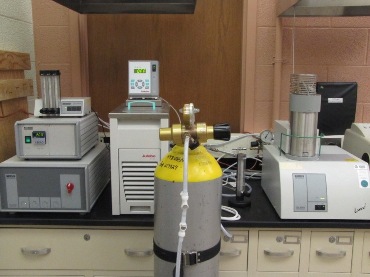

The laboratory of Prof. Kumta is equipped with state-of-the-art facilities for low temperature chemical processing of ceramics. Following is a brief description of the major equipment that is currently available in the laboratory of the Principal Investigator.

A complete list of equipment and descriptions can be found via this link:

High temperature, high pressure reactor with 500 mL moveable vessel assembly. Temperature up to 500 degrees C. Pressure up to 5000 psi.

General-purpose testing equipment for battery testing, life cycling, and material research. Each channel is a fully functional potentiostat/galvanostat and covers very wide current, voltage and power ranges. Also a useful tool for studying battery packs and chargers.

Includes a variable-range electronic timer, safety interlock system, and shock-mounted electric motor for tabletop operation. A P5 unit is also available for milling materials in larger quantities.

Includes digital processing and touch screen control. Output amplitude is controlled from 0-100%. Includes standard horn and sound enclosure.

Including the Thermcraft Standard “S Line” High Temperature Hinged Tube Furnace (seen below) as well as a Lindberg/Blue M Tube Furnace, Thermo-Scientific Lindberg/Blue M model HTF55322C 1200°C tube furnace, a Lindberg/Blue 1700C box furnace, a 1500°C tube furnace a 1200°C Box Furnace, and a Deltek 1200C bottom loading inert atmosphere hydraulic furnace.

Characterizes the active and support surfaces of catalysts, to determine the high surface areas of adsorbents, and to determine the microporosity and hydrogen storage capacity of various nano materials.

Offers simultaneous thermogravimetric and calorimetric analyses from room temperature into the high temperature range of 1650°C. Vacuum-tight construction also provides for pure atmospheres during analysis.

Top precision spin coating systems, designed for low volume production coating applications and to apply a variety of liquid materials to planer substrate.

PC controlled,electronic load bank and fuel cell system controller, operating on ElectroChem's proprietary Windows-based software system. The user can program the flow rate, temperature, and humidification of the reactant gases and the load to the fuel cell.

Determines pore size distribution, pore volume, and apparent density of solid/powder samples. Pore diameter range: 360 mm-5 nm.

Fully automatic. Determines the true density and volume by measuring pressure change of helium within a calibrated volume. Measures samples having volumes above 1 cc maximum

Measurement of absorbance, fluorescence, and luminescence for biological assays

Sterilization of tissue culture supplies and tools

Freeze-drying and lyophilization of samples

Observation of cell culture and fluorescence staining

A Philips PANalytical self-enclosed analytical powder diffractometer for crystal structure analysis equipped with a goniometer and X'Celerator

Equipped with a diamond ATR a KBr beamsplitter (7800 - 350 cm-1), a solid substrate far-IR beamsplitter (700-50 cm-1) X700, and a gold monoflect dual detector optical system. It is connected to the TGA unit for the gas phase analysis.

Compact bench-mounted simultaneous ICP spectrometer unit, based on a RF induced plasma emission source, a purged Echelle polychromator and Charge Injection Device (CID) array detector and includes as standard: - A 4 channel, 12 roller peristaltic pump under full computer control feeding a standard glass cyclonic spray chamber via a glass concentric nebuliser.

Three 3-D inkjet printers (ExOne and Z-Corp) for printing ceramic and metallic particles

Anatech USA brand sputtering machine

Brookfield brand, model DV-II+ Pro

Plasma enhanced CVD from MTI Corporation