Active Projects

BRIDGE PROJECTS

A NOVEL METHODOLOGY FOR STRUCTURAL OPTIMIZATION OF BRIDGE DECKS AGAINST CORROSION

Project Objectives

Create and deploy a novel toolset for the prediction of corrosion based on the structural features of a selected bridge deck. Physics-based numerical models for the prediction of corrosion in reinforced concrete decks will be developed. This new modeling framework will be embedded in an optimization framework to develop new best practices for bridge deck corrosion mitigation to guide both the design of new systems and the maintenance of existing ones. The ultimate goal is to identify the complex interrelationships between the temporal and spatial frequency of salt application and the corrosion mitigation strategies in place. Then, this new information will be combined with reliability-based optimization to provide guidelines for the operational control of bridge decks subject to corrosion mechanisms.

Create and deploy a novel toolset for the prediction of corrosion based on the structural features of a selected bridge deck. Physics-based numerical models for the prediction of corrosion in reinforced concrete decks will be developed. This new modeling framework will be embedded in an optimization framework to develop new best practices for bridge deck corrosion mitigation to guide both the design of new systems and the maintenance of existing ones. The ultimate goal is to identify the complex interrelationships between the temporal and spatial frequency of salt application and the corrosion mitigation strategies in place. Then, this new information will be combined with reliability-based optimization to provide guidelines for the operational control of bridge decks subject to corrosion mechanisms.

Dr. John Brigham: brigham@pitt.edu

Bridge Load Ratings

Project Objectives

This project addresses the challenge of increasing bridge postings and closures due to aging infrastructure and growing load demands. The primary objective is to create digital twins of selected Pennsylvania concrete tee beam bridges, employing commercial finite element (FE) software like ANSYS. These bridges will be analyzed using both detailed numerical models and simplified representations that simulate an automated process. The aim is to assess whether current load ratings, which lead to conservative postings, are justified. By comparing the results and evaluating them against the Bridge Safety Inspection Manual Publication 238, 2022 Edition, this project intends to determine the validity of bridge postings and, if necessary, develop a software tool to supplement current analysis methodologies. The project's outcomes will include accurate FE models based on engineering drawings, insights into the appropriateness of current load ratings, and the potential creation of a software tool to enhance bridge load rating practices.

This project addresses the challenge of increasing bridge postings and closures due to aging infrastructure and growing load demands. The primary objective is to create digital twins of selected Pennsylvania concrete tee beam bridges, employing commercial finite element (FE) software like ANSYS. These bridges will be analyzed using both detailed numerical models and simplified representations that simulate an automated process. The aim is to assess whether current load ratings, which lead to conservative postings, are justified. By comparing the results and evaluating them against the Bridge Safety Inspection Manual Publication 238, 2022 Edition, this project intends to determine the validity of bridge postings and, if necessary, develop a software tool to supplement current analysis methodologies. The project's outcomes will include accurate FE models based on engineering drawings, insights into the appropriateness of current load ratings, and the potential creation of a software tool to enhance bridge load rating practices.

Dr. Piervincenzo Rizzo: pir3@pitt.edu

GEOTECH PROJECTS

Analysis of Reoccurring Landslides in SWPA to Advance Hazard and Risk Estimates

Project Objectives

The project will examine landslide reoccurrence in southwestern Pennsylvania and its interaction with human landscape modifications. By analyzing regional landslide data and conducting spatial analysis, the project seeks to identify patterns and develop mechanistic models of reoccurrence. Multivariate analysis will compare environmental factors between reoccurring and stable/new landslides. The results will identify high-risk areas, guiding mitigation efforts and informing effective repair methods in landslide-prone areas.

The project will examine landslide reoccurrence in southwestern Pennsylvania and its interaction with human landscape modifications. By analyzing regional landslide data and conducting spatial analysis, the project seeks to identify patterns and develop mechanistic models of reoccurrence. Multivariate analysis will compare environmental factors between reoccurring and stable/new landslides. The results will identify high-risk areas, guiding mitigation efforts and informing effective repair methods in landslide-prone areas.

Dr. Daniel Bain: dbain@pitt.edu

Advancing Regional Comprehensive Stormwater Management through Cross-Jurisdictional Coordination and Cooperation

Project Objectives

Development of a coordinated set of stormwater meetings ranging from lunch-and-learn training sessions to a full blown second Symposium. These meetings would vary in scope but be aligned in purpose to address the challenges identified in the 2023 Symposium. We envision three primary objectives: 1) Coordination of a series of lunch time training session on pertinent stormwater topics.; 2) A series of consensus building meetings between transportation professionals, local officials, and the wider stormwater community to examine the stormwater regulation landscape and determine best practices that could improve stormwater management in cross-jurisdictional infrastructure.; and 3) A Year 7 stormwater symposium to maintain momentum in these stormwater conversations.

Development of a coordinated set of stormwater meetings ranging from lunch-and-learn training sessions to a full blown second Symposium. These meetings would vary in scope but be aligned in purpose to address the challenges identified in the 2023 Symposium. We envision three primary objectives: 1) Coordination of a series of lunch time training session on pertinent stormwater topics.; 2) A series of consensus building meetings between transportation professionals, local officials, and the wider stormwater community to examine the stormwater regulation landscape and determine best practices that could improve stormwater management in cross-jurisdictional infrastructure.; and 3) A Year 7 stormwater symposium to maintain momentum in these stormwater conversations.

Dr. Daniel Bain: dbain@pitt.edu

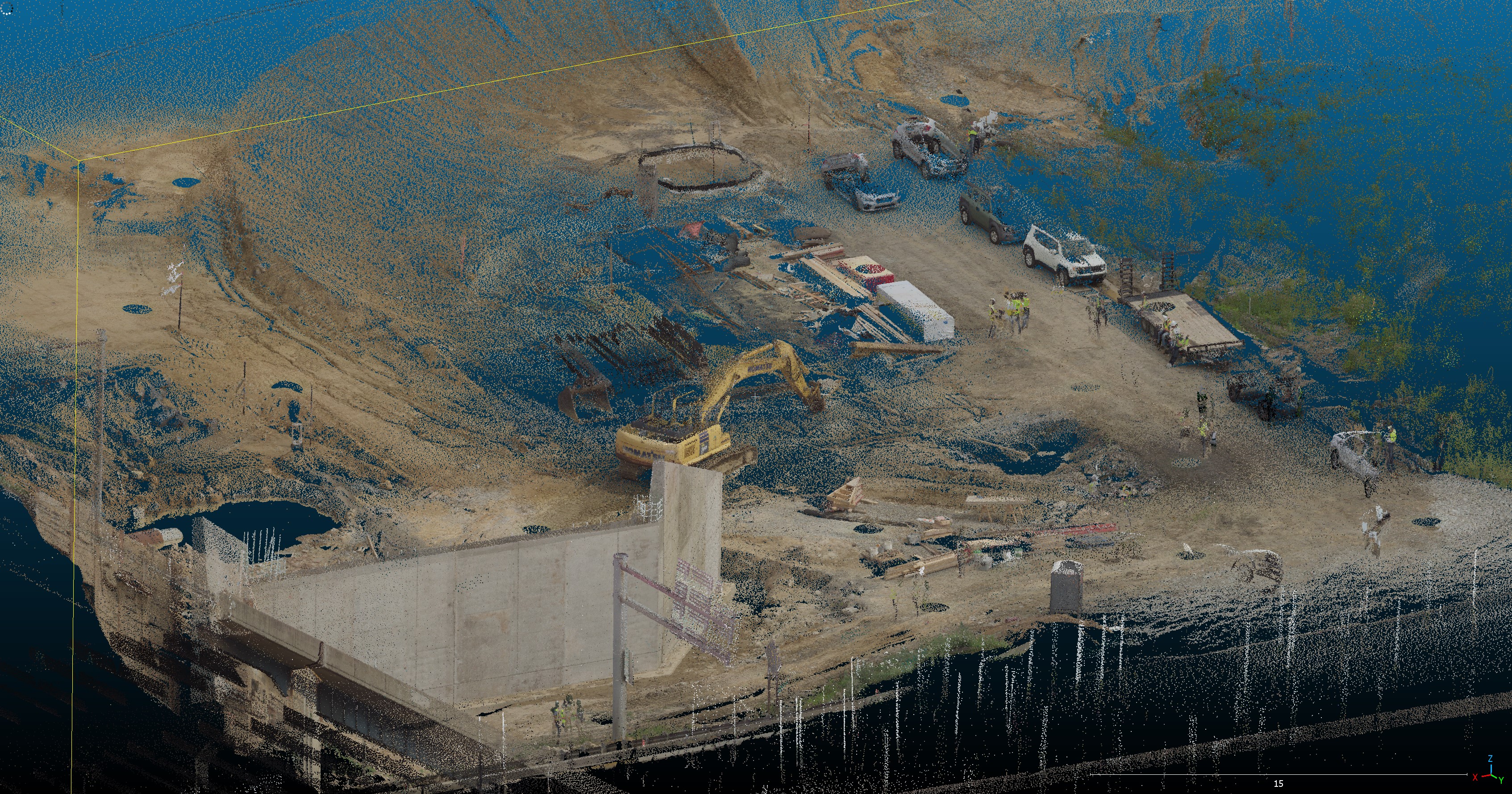

Improved Collection of Earth-Work Quantities Utilizing UAV-Based LiDAR

Project Objectives

This project aims to enhance the accuracy of earthwork estimation using UAV-mounted LiDAR and RGB sensors to improve 3D modeling of large-scale construction sites. The study will include a two-part case study: a workshop to educate stakeholders on UAV-based modeling and a field demonstration showcasing real-world applications for earthwork planning and management. By integrating advanced surveying technologies, the project seeks to reduce cost overruns, optimize material usage, and improve efficiency in balancing earthwork quantities for large infrastructure projects.

This project aims to enhance the accuracy of earthwork estimation using UAV-mounted LiDAR and RGB sensors to improve 3D modeling of large-scale construction sites. The study will include a two-part case study: a workshop to educate stakeholders on UAV-based modeling and a field demonstration showcasing real-world applications for earthwork planning and management. By integrating advanced surveying technologies, the project seeks to reduce cost overruns, optimize material usage, and improve efficiency in balancing earthwork quantities for large infrastructure projects.

Dr. Alessandro Fascetti: fascetti@pitt.edu

Common Sense Compaction for Soils/Embankments

Project Objectives

Assess the suitability of Dynamic Cone Penetrometer and Lightweight Deflectometer technologies for compaction quality control in Pennsylvania conditions. If deemed effective, develop recommendations for a specification that establishes acceptance criteria based on these technologies. Ultimately, the project will deliver actionable insights and recommendations, aiming to enhance the efficiency, accuracy, and safety of soil and embankment compaction practices in Pennsylvania.

Assess the suitability of Dynamic Cone Penetrometer and Lightweight Deflectometer technologies for compaction quality control in Pennsylvania conditions. If deemed effective, develop recommendations for a specification that establishes acceptance criteria based on these technologies. Ultimately, the project will deliver actionable insights and recommendations, aiming to enhance the efficiency, accuracy, and safety of soil and embankment compaction practices in Pennsylvania.

Dr. Lev Khazanovich: lev.k@pitt.edu

Dr. Lucio Salles de Salles: lssite@rit.edu

MATERIALS PROJECTS

DEVELOPING LIGHT-WEIGHT AND HIGH-PERFORMANCE METAMATERIAL CONCRETE

Project Objectives

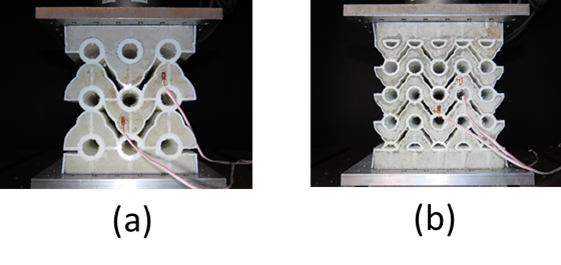

Develop a “metamaterial Light-Weight-Concrete (LWC)” technology to fabricate lightweight and high-performance structural elements, with potential applications for pavement systems, bridge decks, and prefabricated bridge elements. A suite of metamaterial LWC systems with tunable compressive strength and ductility will be evaluated. A range of selected metamaterial lattices will be 3D printed and extensive numerical and experimental studies will be performed to evaluate and predict the mechanical properties of LWC cubes and beams reinforced by the MM lattices. The goal is to design LWC materials with a minimum compressive strength of 50 MPa, minimum toughness of 10 kN⋅mm, and maximum unit weight of 1200kg/m3.

Develop a “metamaterial Light-Weight-Concrete (LWC)” technology to fabricate lightweight and high-performance structural elements, with potential applications for pavement systems, bridge decks, and prefabricated bridge elements. A suite of metamaterial LWC systems with tunable compressive strength and ductility will be evaluated. A range of selected metamaterial lattices will be 3D printed and extensive numerical and experimental studies will be performed to evaluate and predict the mechanical properties of LWC cubes and beams reinforced by the MM lattices. The goal is to design LWC materials with a minimum compressive strength of 50 MPa, minimum toughness of 10 kN⋅mm, and maximum unit weight of 1200kg/m3.

Dr. Amir Alavi: alavi@pitt.edu

Material Compatible Repairs Evaluation

Project Objectives

Partial-depth repair of concrete pavements and bridge decks is a rehabilitation technique that restores localized surface distresses in the upper one-third to one-half of a concrete slab depth. With proper design and construction, partial-depth repair should last as long as the surrounding concrete pavement making it a cost-effective and sustainable alternative to more costly and invasive rehabilitation options. Past studies have identified two major reasons for premature failures of partial depth repairs: (a) inability to achieve and keep adequate bond between the repair and the existing pavement due to improper repair material selection; and (b) incorrect repair dimensions.

Partial-depth repair of concrete pavements and bridge decks is a rehabilitation technique that restores localized surface distresses in the upper one-third to one-half of a concrete slab depth. With proper design and construction, partial-depth repair should last as long as the surrounding concrete pavement making it a cost-effective and sustainable alternative to more costly and invasive rehabilitation options. Past studies have identified two major reasons for premature failures of partial depth repairs: (a) inability to achieve and keep adequate bond between the repair and the existing pavement due to improper repair material selection; and (b) incorrect repair dimensions.

To address the incompatibility issues between in-situ concrete and repair material, a previous research project entitled “Material Compatible Repairs (MCR) for Concrete Pavements and Bridge Decks” was conducted as part of IRISE’s first year program. Based on laboratory studies, the research shed light on the importance of using MCRs and best practices to develop a performance engineered repair material (PERM) to be used for the MCR. In this project, extensive and comparative testing is needed to validate and demonstrate the results of this previous research in the field. Concurrently, for the same repairs, investigate the ability of ultrasonic tomography testing to provide reliable information for required partial depth repair dimensions and evaluate bond condition after repair placement.

Dr. Steven Sachs: sgs15@pitt.edu

Concrete Mixtures with Half the Carbon Footprint

Project Objectives

The objective of this research is to identify and evaluate alternatives that could be used to reduce the carbon footprint of a PennDOT concrete paving mixture in half. In this project, the use of more sustainable concrete paving mixtures will be investigated. Locally available industrial by-products that could potentially be used in the concrete mixture will be investigated for potential inclusion in the study.

The objective of this research is to identify and evaluate alternatives that could be used to reduce the carbon footprint of a PennDOT concrete paving mixture in half. In this project, the use of more sustainable concrete paving mixtures will be investigated. Locally available industrial by-products that could potentially be used in the concrete mixture will be investigated for potential inclusion in the study.

Dr. Julie Vandenbossche: jmv7@pitt.edu

PAVEMENTS PROJECTS

PREDICTION OF DOWEL CORROSION AND EFFECT ON PERFORMANCE OF CONCRETE PAVEMENTS

Project Objectives

1) Determine corrosion mechanisms and critical factors in dowels using currently available models and databases, 2) Experimentally investigate corrosion development in a novel accelerated load test to quantify resulting loss of dowel performance, 3) Build predictive performance models using modeling and experimental results, which will be validated with field data, 4) Create a set of guidelines based on the results to inform pavement design and management practices.

1) Determine corrosion mechanisms and critical factors in dowels using currently available models and databases, 2) Experimentally investigate corrosion development in a novel accelerated load test to quantify resulting loss of dowel performance, 3) Build predictive performance models using modeling and experimental results, which will be validated with field data, 4) Create a set of guidelines based on the results to inform pavement design and management practices.

Dr. Julie Vandenbossche: jmv7@pitt.edu

DESIGN AND CONSTRUCTION OF TWO-LIFT CONCRETE PAVEMENTS FOR PENNSYLVANIA

Project Objectives

Two-lift concrete pavement construction, a technique that involves the placement of two wet-on-wet layers of concrete with different mixes, can balance the need for different materials in different depths of the concrete slab. This project will develop design and construction recommendations for two-lift concrete pavements for Pennsylvania conditions. This will involve testing appropriate concrete mixes for both top and bottom layers with a focus on the former’s high-performance needs and the latter’s economical and sustainable aspects. An experimental section will be evaluated, focusing on the challenges of working consecutively with two pavers and two concrete mixes. A comprehensive evaluation of the bonding conditions between the two layers will be performed and documented using non-destructive methods. The potential cost saving and reduction in carbon footprint will be evaluated.

Two-lift concrete pavement construction, a technique that involves the placement of two wet-on-wet layers of concrete with different mixes, can balance the need for different materials in different depths of the concrete slab. This project will develop design and construction recommendations for two-lift concrete pavements for Pennsylvania conditions. This will involve testing appropriate concrete mixes for both top and bottom layers with a focus on the former’s high-performance needs and the latter’s economical and sustainable aspects. An experimental section will be evaluated, focusing on the challenges of working consecutively with two pavers and two concrete mixes. A comprehensive evaluation of the bonding conditions between the two layers will be performed and documented using non-destructive methods. The potential cost saving and reduction in carbon footprint will be evaluated.

Dr. Lev Khazanovich: lev.k@pitt.edu

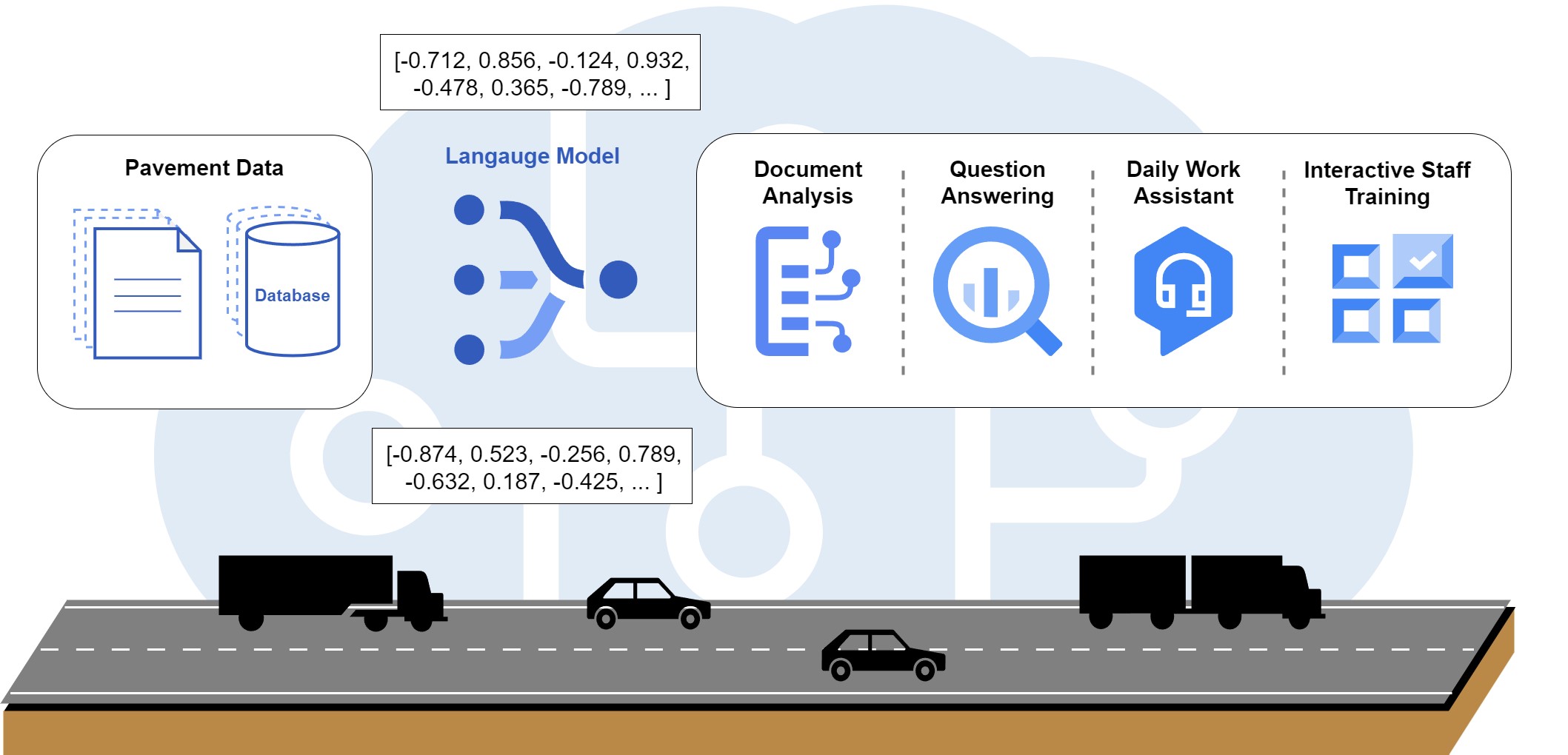

Adaptation of a Large Language Model for Facilitating Pavement-Related Information Retrieval and Knowledge Discovery

Project Objectives

The goal is to create an Artificial Intelligence (AI) model that can process and generate natural language to answer common pavement engineering and pavement construction questions quickly and accurately. The model will be able to answer questions about pavement design, mix design, specifications, best construction practices, pavement maintenance and rehabilitation, pavement management, as well as pavement testing and evaluation. It will have a human-like ability to provide reliable answers and will be suitable for interactive training. The tool will have the capability to assess a user's knowledge by posing questions and offering feedback on their answers, making it an effective tool for skill development and evaluation. Additionally, the model will be able to assist pavement engineers in retrieving and summarizing relevant information from a large corpus of pavement-related literature. This can facilitate knowledge discovery and help pavement engineers stay up-to-date with the latest developments in their field.

The goal is to create an Artificial Intelligence (AI) model that can process and generate natural language to answer common pavement engineering and pavement construction questions quickly and accurately. The model will be able to answer questions about pavement design, mix design, specifications, best construction practices, pavement maintenance and rehabilitation, pavement management, as well as pavement testing and evaluation. It will have a human-like ability to provide reliable answers and will be suitable for interactive training. The tool will have the capability to assess a user's knowledge by posing questions and offering feedback on their answers, making it an effective tool for skill development and evaluation. Additionally, the model will be able to assist pavement engineers in retrieving and summarizing relevant information from a large corpus of pavement-related literature. This can facilitate knowledge discovery and help pavement engineers stay up-to-date with the latest developments in their field.

Dr. Lev Khazanovich: lev.k@pitt.edu

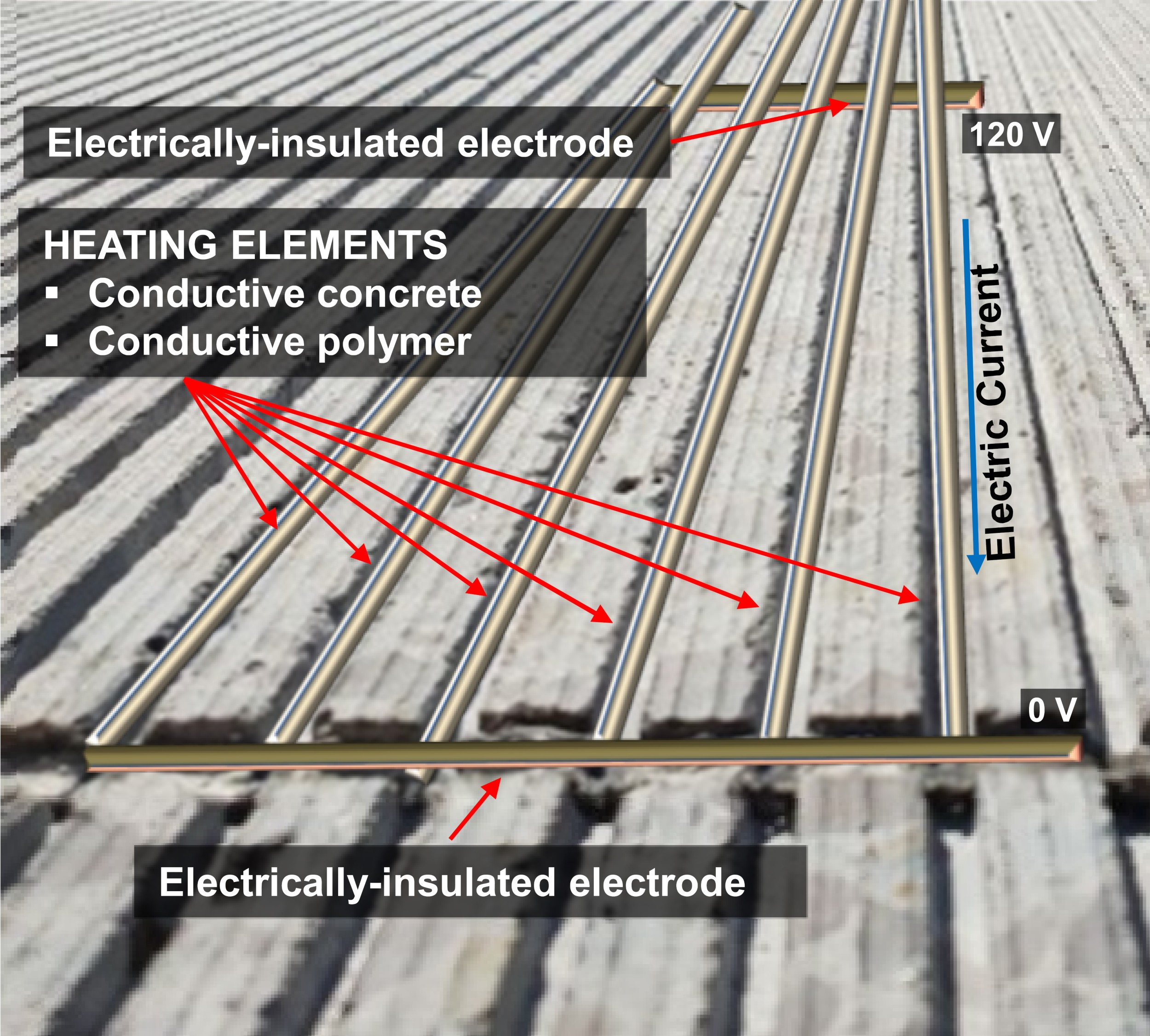

Self-Heating Concrete Pavements Systems with Surface-Mounted Heating Elements

Project Objectives

This project explores the feasibility of using surface-mounted heating elements to develop self-heating concrete pavements for automated snow and ice removal. Unlike traditional deicing methods, this technology reduces environmental impact and enhances pavement durability by eliminating the need for deicing chemicals. The study will investigate conductive concrete modified for surface heating, alternative heating elements, and energy-efficient designs powered by renewable energy. If successful, this solution could provide a scalable, cost-effective, and sustainable alternative for winter road maintenance on both existing and new pavements.

This project explores the feasibility of using surface-mounted heating elements to develop self-heating concrete pavements for automated snow and ice removal. Unlike traditional deicing methods, this technology reduces environmental impact and enhances pavement durability by eliminating the need for deicing chemicals. The study will investigate conductive concrete modified for surface heating, alternative heating elements, and energy-efficient designs powered by renewable energy. If successful, this solution could provide a scalable, cost-effective, and sustainable alternative for winter road maintenance on both existing and new pavements.

Dr. Amir Alavi: alavi@pitt.edu

WORKER SAFETY PROJECTS

AI Safety Assistant

Project Objectives

This project will develop an AI/LLM tool to aid safety personnel in the highway construction industry. The tool will focus on two primary tasks: firstly, it will assist in procuring daily work activity plans with a safety focus, aiding safety management in communicating specific hazards associated with various activities and inspection practices. Secondly, as an auxiliary feature, the tool will serve as a data entry tool to improve the quality of accident reporting, filling any knowledge gaps that new employees might have, and enhancing future analysis and safety data dissemination. By incorporating innovative Natural Language Processing techniques, this tool can help ensure more accurate and comprehensive incident reports, overcoming the limitations of manually curated narratives.

This project will develop an AI/LLM tool to aid safety personnel in the highway construction industry. The tool will focus on two primary tasks: firstly, it will assist in procuring daily work activity plans with a safety focus, aiding safety management in communicating specific hazards associated with various activities and inspection practices. Secondly, as an auxiliary feature, the tool will serve as a data entry tool to improve the quality of accident reporting, filling any knowledge gaps that new employees might have, and enhancing future analysis and safety data dissemination. By incorporating innovative Natural Language Processing techniques, this tool can help ensure more accurate and comprehensive incident reports, overcoming the limitations of manually curated narratives.

Dr. Lev Khazanovich: lev.k@pitt.edu

Other

Developing and Applying Methodologies to Quantify the Benefits of IRISE Projects

This project aims to develop and apply unique methodologies to quantify the benefits of IRISE's completed and in-process research projects. By focusing on up to five selected projects, the team will evaluate the improvements in transportation infrastructure longevity and reductions in life cycle costs resulting from IRISE research. The project involves analyzing case studies, crash data, and statewide construction data to measure the impact of research findings. It will also provide an evaluation and recommendation for broad-scale implementation of these findings.

Supervised Learning for Classification of High-Resolution LiDAR Point Clouds

Project Objective

Main objective of the proposed research is to improve accuracy and efficiency of surveying operations, ultimately paving the way for novel 3-D project delivery workflows. This requires the development of novel classification tools for the supervised segmentation of 3-dimensional point clouds by combining digital models, a comprehensive database of laser-based reconstructions, and computer vision libraries such as OpenCV, Scikit-Image, and TorchVision. We will take a Supervised Learning approach in the delivery of the project, to directly include expert knowledge in the classification algorithms. This will be achieved by classifying available point clouds and using this information to devise infrastructure-specific segmentation algorithms. The ultimate objective is the preparation of a report and a set of guidelines to maximize outreach and direct applicability of the research.

Main objective of the proposed research is to improve accuracy and efficiency of surveying operations, ultimately paving the way for novel 3-D project delivery workflows. This requires the development of novel classification tools for the supervised segmentation of 3-dimensional point clouds by combining digital models, a comprehensive database of laser-based reconstructions, and computer vision libraries such as OpenCV, Scikit-Image, and TorchVision. We will take a Supervised Learning approach in the delivery of the project, to directly include expert knowledge in the classification algorithms. This will be achieved by classifying available point clouds and using this information to devise infrastructure-specific segmentation algorithms. The ultimate objective is the preparation of a report and a set of guidelines to maximize outreach and direct applicability of the research.

Dr. Alessandro Fascetti: fascetti@pitt.edu