Facilities

Acoustic Sensing Lab

Located at the Energy Innovation Center, Room 135

- PI: Paul Ohodnicki, PhD

- PI: Khurram Naeem

The Acoustic Sensing Lab focuses on the development and application of advanced acoustic and ultrasonic sensing technologies for Structural Health Monitoring (SHM), and nondestructive evaluation. The lab specializes in fiber-optic and photonic sensor systems, innovative sensor designs, and integrating advanced signal processing techniques including Machine Learning framework to detect, characterize and classify acoustic waves across a wide frequency range. Key research areas include guided wave inspection, distributed acoustic sensing (DAS), and high-sensitivity ultrasonic detection using optical sensors. Besides, the lab also focus on developing custom optical sensing systems for high-resolution strain and temperature measurement, namely Rayleigh OFDR and Raman distributed temperature sensor (DTS). The lab aims to create robust, high-resolution, and field-deployable solutions for applications in energy infrastructure including oil-and-gas pipelines, and marine sectors.

Gas and Temperature Sensing Setup

Located at the Energy Innovation Center, Room #139C

- PI: Paul Ohodnicki, PhD

- Faculty/Researcher: Tulika Khanikar

- Faculty/Researcher: Yang Duan Su

The temperature and gas sensing setup is dedicated to fiber optic sensor experiments. It is equipped with various gases including CO2 (both % and ppm level), H2, CH4, N2, Synthetic air. The tube furnace has a temperature control range of 200C-1200C.

Laser Heated Pedestal Growth (LHPG)

Located at the Energy Innovation Center

- PI: Paul Ohodnicki, PhD

- Faculty/Researcher: Jun Young Hong

- Faculty/Researcher: Dolendra Karki

The Laser Heated Pedestal Growth (LHPG) facility at the University of Pittsburgh enables the fabrication of high-quality single-crystal fibers using a simplified, low-cost optical setup. The system features real-time diameter monitoring, a PID-controlled loop for laser power stability, and the capability to grow fibers from both single-crystalline and polycrystalline source rods. This in-house platform supports research into SCF-based sensing, photonics, and high-temperature applications.

Main Components:

- CO₂ laser (Firestar 30 OEM, Synrad, λ=10.6 μm) with 30W max. power

- He-Ne red laser for thealignment - Beam expander

- Off-axis parabolic mirror

- ZnSe beam combiner

- Top and Bottom motor

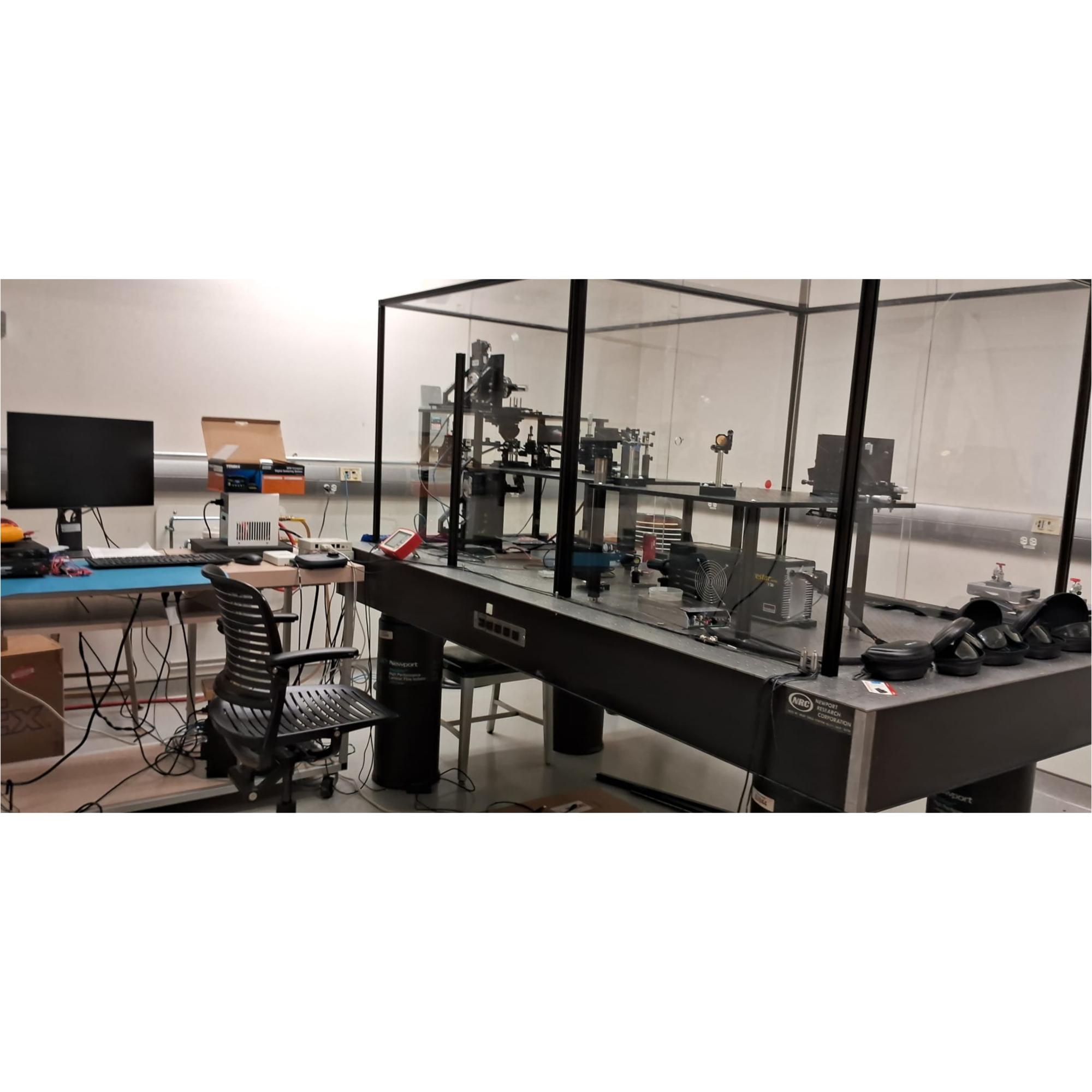

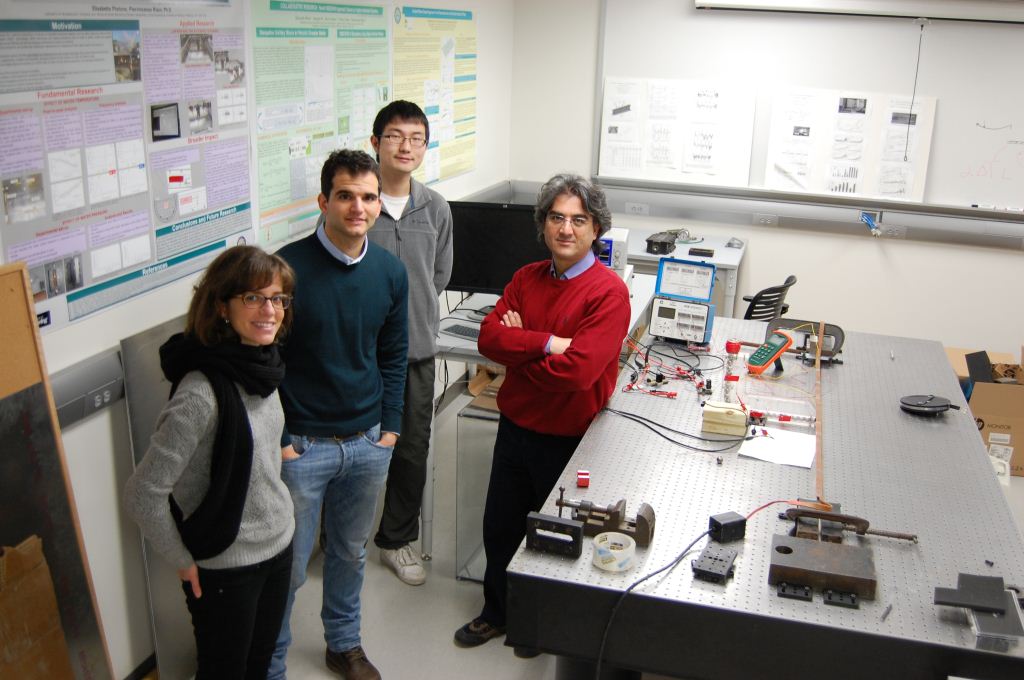

Laboratory for NDE and SHM Studies

Located in Benedum Hall, Room 724

- PI: Piervincenzo Rizzo, Ph.D

Laboratory for Nondestructive Evaluation and Structural Health monitoring studies was established by Dr. Rizzo in 2006 upon his arrival at the University of Pittsburgh. In September 2012 the laboratory was re-located in a totally renovated floor. The laboratory consists of about 900 square feet of dust-free space, which contains the state-of-the-art equipment of some of the most widely used Nondestructive Evaluation (NDE) and structural health monitoring(SHM) methods. The laboratory is equipped to conduct research and development in Acoustic Emission, Ultrasonic Testing, Modal Analysis, Infrared Thermography, Optical testing, Electrotechnical Impedance, and Acoustics.

Intelligent Nonlinear Systems Lab (Bajaj Research Lab)

Located in Benedum Hall

- PI: Nikhil Bajaj

The Intelligent Nonlinear Systems Lab is a lab space in Benedum Hall at the University of Pittsburgh, that has capabilities needed for prototyping and testing sensing systems. The lab is equipped with electronic test equipment (oscilloscopes, power supplies, function generators, spectrum analyzers, lock-in amplifiers) as well as equipment capable of bespoke signal processing and control through state-of-the-art microcontrollers, FPGAs, and DSP systems. Some fabrication equipment (3D printers, small milling machines, PCB printing machine, soldering tools) is also available. The lab houses a Whisper Room sound isolation booth for sensitive acoustic measurements, as well as multiple vibration isolation tables, which house two laser Doppler vibrometer systems, capable of sub-nm vibration measurement at frequencies up to 24 MHz. For MEMS devices, one of the vibrometers can scan at the microscopic level, visualizing deformation modes of MEMS devices both out-of-plane and in-plane - these devices can be analyzed under vacuum or certain gas exposures in our probe station.

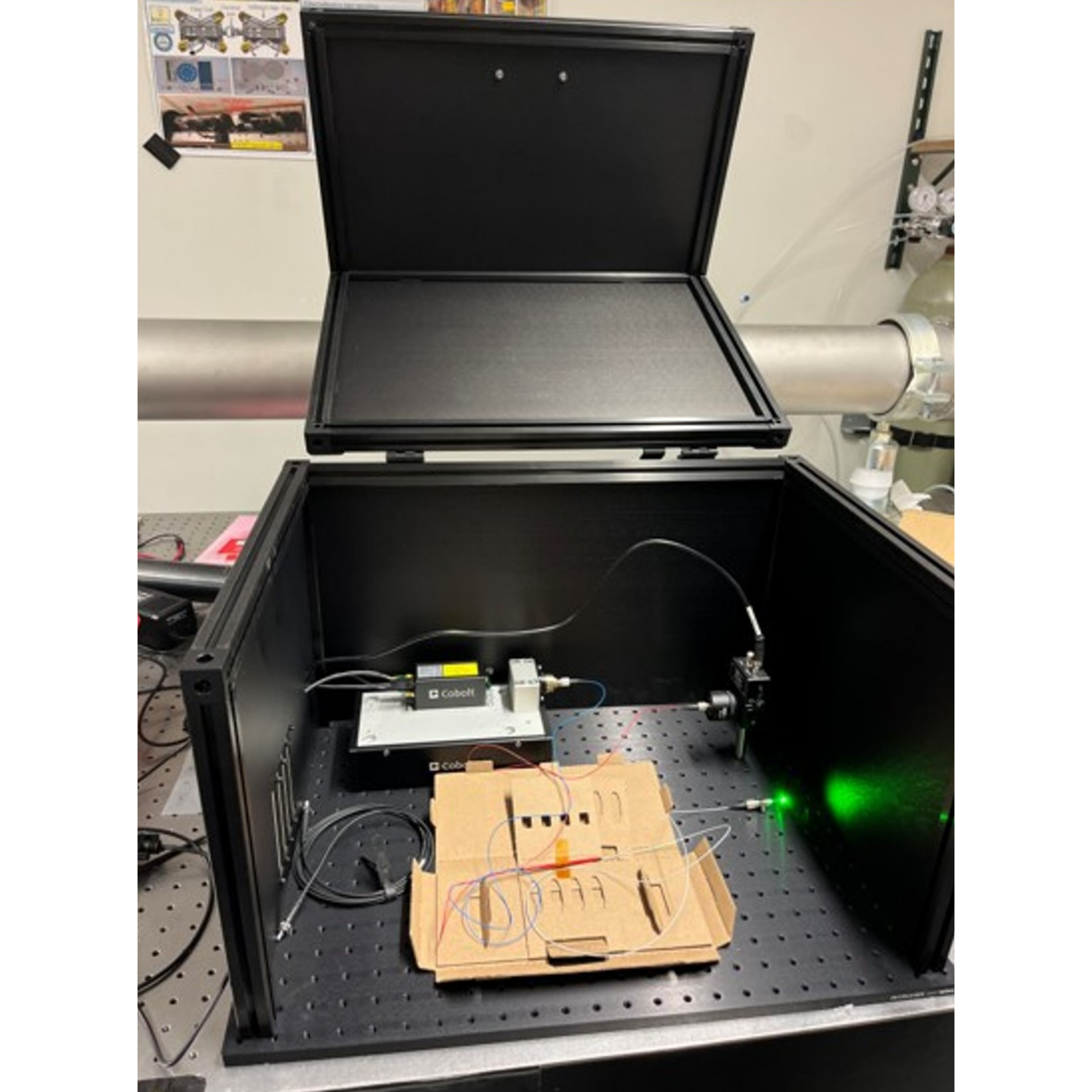

Quantum Sensing and Optical Interrogation Setup

Located at the Energy Innovation Center

- PI: Paul Ohodnicki

- Faculty/Researcher: Jun Young Hong

Our quantum sensing setup at the University of Pittsburgh enables optical interrogation of nitrogen-vacancy (NV) centers in nanodiamond composites.The system integrates a 532 nm laser source coupled through a multimode circulator to a custom-fabricated ball-lensed optical fiber, coated with apolymer-nanodiamond (ND) composite. The setup includes an RF signal generator for microwave excitation via a magnetic coil, with optical collectionmanaged through a collimator, long-pass filter (>550 nm), and a plano-convex lens. Emitted fluorescence is analyzed via a spectrometer or avalanchephotodiode (APD). Housed in a light-isolated enclosure, this setup supports experiments for ODMR-based magnetic field sensing and photonicintegration research.

CO₂ and pH Sensing Development Spaces

Located in Benedum Hall, Room 532 (MMCL)

- PI: Paul Ohodnicki

- Faculty/Researcher: Jahid Inam Chowdhury

- Faculty/Researcher: Devika Mohan

The dedicated setups for development CO₂ and pH sensing using fiber optics are housed at the Materials Metrology, Characterization and Learning (MMCL) shared space at Benedum Hall. The CO₂ sensing setup is capable of real-time monitoring of transmitted light intensity through the fiber, enabling precise detection of gas-induced optical changes in the sensing layer. The pH sensing setup is intended for optical fiber-based sensing of pH variations in laboratory seawater, equipped with a pH flow control system and a VIS-NIR spectrometer for measuring and analyzing the intensity variations in the transmitted light in response to pH variations.

The CO₂ and pH sensing development also counts with the support of advance equipment housed at the Nanoscale Fabrication & Characterization Facility (NFCF).