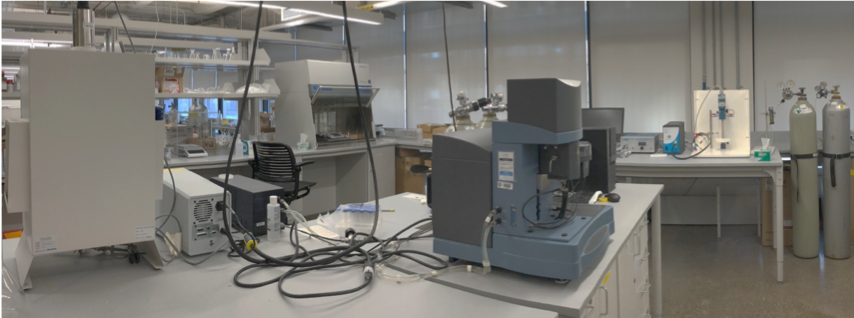

The Environmental Engineering Laboratory conducts research and provides analytical capabilities in the area of environmental science and engineering. The facility consists of approximately 10,000 square feet, divided into laboratory bays and a centralized analytical equipment core.

Faculty conducting research in the environmental engineering laboratory include:

- Dr. Leonard Casson

- Dr. Leanne Gilbertson

- Dr. Sarah Haig

- Dr. Carla Ng

- Dr. Radisav Vidic

- Dr. Meng Wang

We have a wide range of analytical capabilities for performing environmental chemistry, microbiology, and materials characterization.

Environmental Chemistry Characterization:

- Agilent 5100 VDV inductively coupled plasma optical emission spectrometer (ICP-OES);

- Agilent 7820 Gas Chromatograph with 5977E mass spectrometric detector and 7693A autoinjector

- Dionex ICS-1100 Ion Chromatography System with conductivity detector, ion suppressors and AS-DV autoinjector

- Agilent 1200 series HPLC with degasser, quaternary pump, autoinjector, thermostatically controlled column compartment, VWD detector and refractive index detector

- CEM MARSXpress microwave digester

- Genesys 10S UV-visible spectrophotometer

- Thermo Evoluton 201 spectrophotometer

- Hach DR3900 spectrophotometer

- Hewlett Packard 5890 Series-II Gas Chromatograph with electron capture and flame ionization detectors (GC-ECD/FID)

- Hach 2100-A Turbidimeter

- Hach COD digesters

- pH meters

- YSI dissolved oxygen probes

Materials Characterization:

- TA Instruments Q5000 IR Thermogravimentic Analyzer

- Anton Paar Litesizer 500 particle analyzer

- Microtrac S3500 laser particle sizer

- Anton Paar SurPASS3 zeta potential analyzer

- PINE Wavedriver 20 Bipotentiostat with rotating ring-disk electrode

- Additional materials characterization is supported by the Petersen Institute of Nanoscience and Engineering (hyperlink PINSE to webpage: http://www.nano.pitt.edu/node/211)

Microbiology Characterization:

- BioTek Synergy HT and HTX microplate readers

- EVOS FL imaging system

- BioRad CFX Connect real-time PCR System

- Thermo Arktik thermocycler

- Thermo EC300 horizontal gel electrophoresis systems

- MarketForge Sterilmatic SteamE autoclave

- Tuttnauer 3870E autoclave

- UVP Transilluminator

- Baker BioChemGard laminar flow hoods

- Baker SterilGard laminar flow hoods

- Fisher Micromaster phase-contrast microscopes

- Quebec colony counter

- Thermo MaxQ incubator-shakers

- Isotemp CO2 Incubator with IR temperature control and HEPA filtration

Supporting Equipment

- Sorvall Legend X1R refrigerated centrifuge

- Fisher Accuspin 400 centrifuge

- Thermo Accuspin Micro 17R refrigerated microcentrifuge

- Mettler XPE 26 micro-analytical balance in a LabConco XPert Nano weigh enclosure

- Branson Ultrasonics sonifier S-450 Digital ultrasonic cell disruptor/homogenizer with soundproof enclosure

- Shel Lab gravity oven

- Heratherm forced air oven

- Barnstead Thermolyne 1100C laboratory furnace

- Revco 30 CF -20C freezer

- VWR 13 CF -86C Freezer

- Isotemp 17CF -86C freezer

- Mettler AE-163 and AE-50 Analytical Balances

- Water baths, magnetic stirrers, vortex mixers, hot plates, research grade glassware and supplies

- Extensive chemical library of over 700 reagents.

Collaboration

The Environmental Engineering Laboratory has established collaborations with faculty of the Departments of Chemical and Petroleum Engineering, Geology and Environmental Science, and Chemistry as well as the Graduate School of Public Health. We also collaborate with non-University entities for joint activity in environmental science and technology developments. If you are interested in collaborating, please reach out to one of the environmental engineering faculty listed above.

The University of Pittsburgh Hydraulic Fracturing Laboratory supports research into hydraulic fracture propagation. It includes: 1) a true-triaxial cell, including hydraulic pump and pressure control, capable of applying up to 20 MPa of stress independently in each of 3 direction to specimens measuring up to 300 mm on a side, 2) multi-axis video monitoring that is enabled by viewing ports in the loading platens of the triaxial cell, backlight sources built into the loading platens, and digital video cameras 3) a syringe pump used for injecting fluid for hydraulic fracturing, 4) combined acoustic emission detection and ultrasound tomography system.

Top: Photo from Modern Shale Gas Development in the United States: A Primer, US Department of Energy, April 2009. Bottom: Polyaxial load frame (left) and acoustic emission detection and ultrasound tomography system (right).

The Laboratory for NDE and SHM studies is a new facility established in September 2006. The facility consists of about 750 square feet of dust-free space, which contains the state-of-the-art equipment in ultrasonic testing and acoustic emission (AE) technology. The laboratory includes:

- Acoustic Emission Instrumentation : one Physical Acoustics Corporation 4-cahnnel PCI/DSP system with waveform module including a notebook computer and AE-Win software; acoustic emission pico, WD, and S14 AE-transducers.

- Ultrasonic Testing Instrumentation : one Tektronix AFG3022 arbitrary function generator (2 output channels); Two Lecroy 4-channels oscilloscope one of which has a PC incorporated running under Windows XP); Commercial broadband Olympus NDT-Panametrics Ultrasonic Transducers; one Olympus NDT-Panametrics high power (max 400 Volts) signal generator. Immersion transducers.

- Optical devices : one high energy pulsed laser; one optical table; lenses, mirrors, posts for high precision optical experiments.

- Modal Testing Instrumentation : 8-channel, line-powered, ICP® sensor signal conditioner; four 1/4 in. pre-polarized condenser microphone, free-field, 4 mV/Pa, 4 to 80k Hz (± 2 dB); Modally Tuned® Impulse Hammer w/force sensor and tips, 0 to 100 lbf, 50 mV/lbf (11.2 mV/N); one 086D80 Miniature Instrumented Impulse Hammer w/force tips, 0 to 50 lbf.

- Miscellaneous Equipment : one National Instrument-PXI 1042Q chassis with arbitrary function generator and multifunction Data Acquisition System; two FLIR Infrared Cameras; five unidirectional and one omnidirectional Audio-Technica microphones; one LCR for electro-mechanical impedance method; five personal computers.

The Department of Civil and Environmental Engineering Pavement Mechanics and Materials Laboratory (PMML) has developed into an all encompassing laboratory equipped to perform a full range of tasks including the casting, curing and testing of everything from concrete specimens to full-scale pavements. The 2700 sq. ft. facility features the latest equipment in both destructive and non-destructive testing of portland cement concrete.

Housed within the lab are two environmentally controlled rooms. The 1007 cu. ft. room can be adjusted to replicate a wide range of environmental conditions for curing portland cement concrete test specimens while the 630 cu. ft. room is maintained at a constant temperature and humidity for determining the drying-shrinkage properties of concrete in accordance with ASTM-157.

The laboratory is equipped with everything needed for measuring basic aggregate properties such as the gradation, absorption capacity and specific gravity, as well as, more detailed characterizations such as determining wear resistance using the Los Angeles abrasion machine or running a micro-deval test. A 5.5 sq. ft. concrete mixer and all other necessary tools for casting concrete specimens are available, as well as equipment for measuring the properties of fresh concrete.

The laboratory is equipped to test the more basic properties of hardened concrete, such as, strength, elastic modulus and Poisson's ratio along with the more elaborate testing equipment needed for measuring such things as the dynamic modulus, thermal coefficient of expansion, fracture toughness of concrete and the surface texture of fractured slabs using a laser profiler and a linear traverse equipment. Some of the sample preparation equipment available in the laboratory includes a concrete saw, core machine and a fume hood for sulfur capping.

Additionally, the laboratory houses a Baldwin compression machine that can be used to apply loads up to 200,000 lbs and a Test Mark compression machine with a capacity of 400,000 lbs. A multitude of tests can also be performed using the MTS TestStar Controller. The controller can be used for performing dynamic testing using a closed-loop servo hydraulic test machine. This system can be fed by either a 10 gpm or 60 gpm hydraulic pump.

Pittsburgh Intelligent Transportation Systems Laboratory (PITTS) Laboratory is a state-of-the-art research and instructional facility which mimics a real-world Traffic Operations Center with corresponding infrastructure and institutional connections to multiple state and local transportation agencies. The lab is housed on the third floor of Swanson building and currently employs several researchers (from postdoctoral research associates to undergraduate research assistants) who work in general area of urban traffic operations and management, traffic signal systems, public transportation systems, etc. All of our staff regularly works both with real-world traffic platforms and high-fidelity microsimulation simulation models thus bridging the gap between reality/field operations and experiments in scientific/controlled environment. Our simulation models are regularly interfaced with various field signal control firmware (Econolite ASC/3, Siemens NextPhase, etc.) including a variety of adaptive software which are important for the execution of the field-like experiments.

The University of Pittsburgh, Swanson School of Engineering, Department of Civil/Environmental Engineering and many other units allowed and allocated many sources that enabled the team to achieve its scientific and research goals professionally and by the latest available technologies. Here are the most prominent sources available to our research group.

Energy Monitoring and Assessment Equipment

We are equipped with energy assessment resources, which enable the collection of measureable data in addition to visual inspection through use of infrared cameras. Tools include, tablets, infrared cameras, smart meters, and voltmeters.

Air Quality Monitoring Equipment

Graywolf software and sensor interface technology measures total volatile organic compounds (TVOC), carbon dioxide (CO2), carbon monoxide (CO), particulate matter (PM0.5, PM1.0, PM2.5, PM5.0, PM10), relative humidity (RH), ozone (O3), temperature, and formaldehyde (HCHO).

Black carbon (BC) samples are collected using AethLab’s Mini Aethalometer. Real-time analysis is conducted by measuring the rate of change in absorption of transmitted light due to continuous collection of aerosol deposits on teflon-coated borosilicate glass fiber filter strips.

Dylos particle counters are used to monitor fine and coarse particles and then data is averaged in ten-second intervals.

Ogawa passive samplers are used to measure NOx and SO2 both indoors and outside of the home.AQMesh monitors are used to collect ambient concentrations of nitric oxide (NOx), carbon monoxide (CO), ozone (O3), atmospheric pressure, and particulate matter (mass and raw counts).

Software Tools

Our lab uses the following software packages:

SimaPro life cycle assessment (LCA) software, including licenses for ecoinvent and other life cycle inventory databases. We also use Athena Impact Estimator for Building LCA.

Statistical analysis software: R, SPSS, SAS, and SPlus.

Computer aided design (CAD) and Building information modeling (BIM): AutoDesk AutoCAD, Revit, SketchUp, and Green Building Studio with updated licenses each year for new editions.

Energy modeling software including EnergyPlus, OpenStudio, eQuest, Design-Builder, Green Building Studio, and Trnsys.

Geo-spatial and mapping software: ArcGIS

The Watkins-Haggart Structural Engineering Laboratory (WHSEL) is the facility at the heart of the experimental structural engineering research efforts at the University of Pittsburgh. This unique facility is located in the sub-basement of Benedum Hall on the main campus of the University of Pittsburgh in Oakland. The Lab is a 4000 ft2 (370 m2) high-bay testing facility with a massive reaction floor. The high-bay testing area is serviced by a 10 ton radio controlled bridge crane and other heavy material handling equipment.

As a compliment to the reaction floor, the Lab also has an extremely versatile self-contained reaction frame and the following major equipment:

- 200 kip (900 kN) servo-hydraulic universal testing machine (UTM) with 15 ft (4.5 m) opening

- 200 kip (900 kN) hydraulic UTM with 6 ft (2 m) opening

- 124 kip (550 kN) servo-hydraulic material test frame

- 20 kip (90 kN) servo-hydraulic fatigue rated UTM

- 500 kip (2220 kN) hydraulic concrete cylinder frame

- 300 kip (1300 kN) reconfigurable test frame

- 50 kip (220) kN fatigue test capacity

- 225 kip (1000 kN) in situ field testing capacity

The laboratory maintains a number of computer controlled data acquisition systems that allow for the automated reading and recording of over 130 discrete channels of instrumentation. The lab has full-scale nondestructive evaluation equipment and field-testing equipment suitable for a variety of in situ test programs.

Since 2004, the laboratory has specialized in conducting large scale fatigue testing at load ranges up to 50,000 pounds (220 kN). To date, fatigue tests totaling over 120 million load cycles have been conducted. The largest tests conducted by the WHSEL team where the 2006 and 2010 tests of multiple 90 foot long (28 m), 70 ton long prestressed girders recovered from the collapsed Lake View Drive Bridge. The lab has conducted extensive research for PennDOT, NCHRP and various other public and private agencies.

Nonconventional Materials Research in WHSEL

The WHSEL is the home of the PITT-NOCMAT, an interdisciplinary research center focusing on the use of nonconventional and vernacular materials in the built environment. Specifically, WHSEL is home to international-leading research into the mechanical and material properties of bamboo. Research conducted in the WHSEL directly supports international efforts at establishing codes and standards for bamboo and other nonconventional construction materials.

PITT-NOCMAT

The mission of PITT-NOCMAT is to engage in cutting edge research, service-learning education, engineering design involving sustainably (typically locally) sourced materials and appropriate technologies that empower communities in need.

The Eco-Env-Hydrology and Water Resources Laboratory focuses on exploring the interactions and feedbacks at the interface between ecological, biological, environmental, and hydrological systems. We emphasize studies, from field measurements to computer model simulations, which govern water, energy, carbon, and nitrogen cycles of the ecosystem. Research at the Lab includes the following areas: (1) designing and building sensors and wireless sensor network and monitoring biological and hydrological variables for studying the health of our eco-environment system; (2) building robust eco-bio-geo-hydrological models; (3) investigating how at different spatial scales the interactions of these cycles affect the health of our environment and ecological systems, (4) studying impacts of these cycles on the transport of nutrients and pollutants, human health, food security, and water resources management; and (5) developing and building hydrologic disaster forecasting and response (HDFR) computer system as a decision-support tool to assess and forecast hydrologic disasters and to help monitor to ensure safe transportation under extreme weather events.

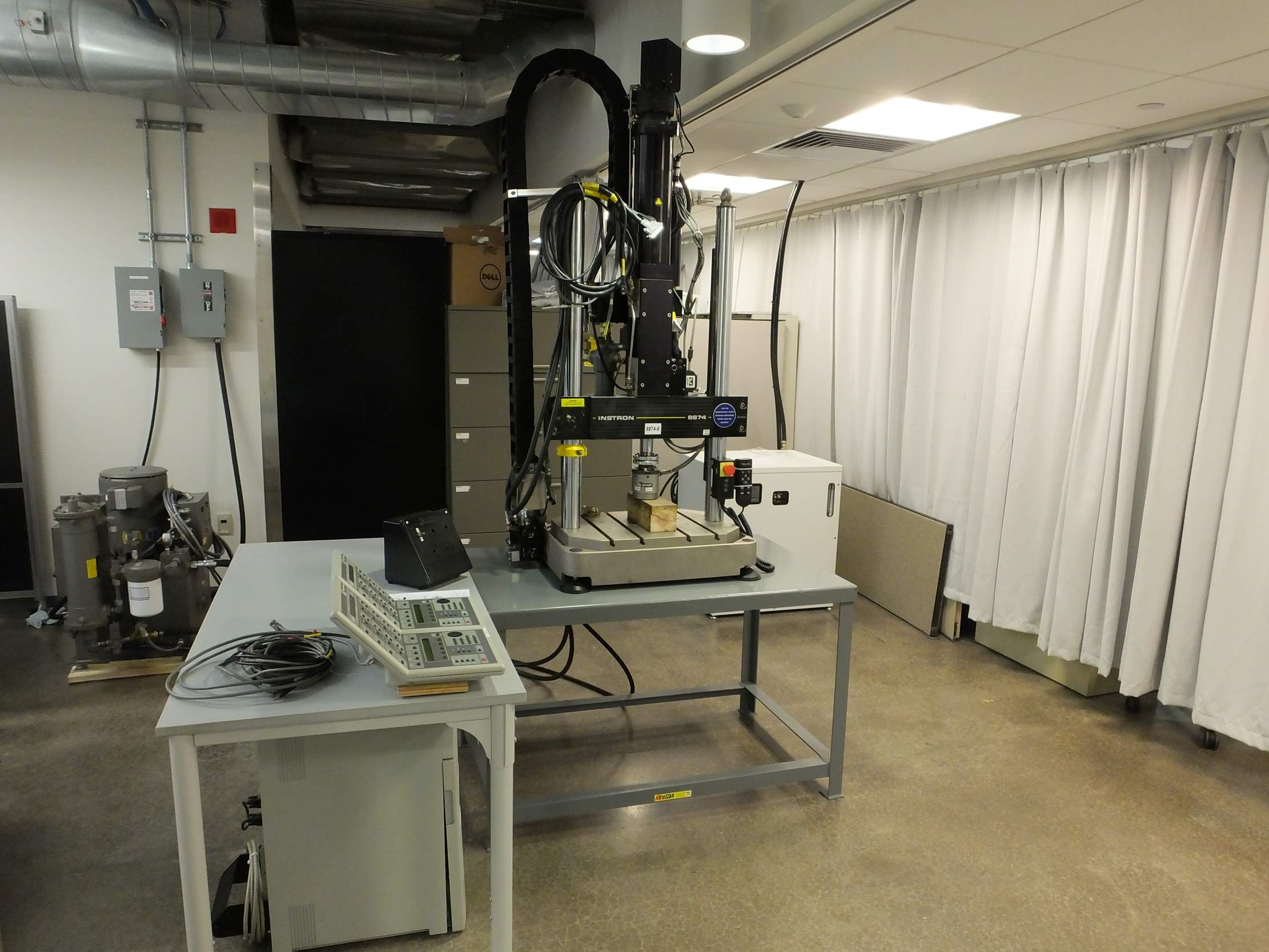

The Intelligent Structures and Architected Materials Research and Testing (ISMART) Laboratory directed by Dr. Amir Alavi is a new facility established in 2019. This facility is located on the second floor of Benedum Hall on the main campus of the University of Pittsburgh in Oakland. The facility consists of approximately 900 square feet of space, including a wet lab and a Biosafety Level 2 (BSL-2) approved space. The ISMART Laboratory facilitates research in the areas of mechanics and electronics of multifunctional materials, self-powered sensing systems, and engineering system informatics. The laboratory includes:

- Instron 8874 Biaxial Servohydraulic Fatigue Testing System

- TestResources Electromechanical Universal Testing Machine

- Raise3D Pro2 3D Printers

- Ultimaker S3 3D Printers

- National Instruments Data Acquisition System (cDAQ-9174, NI 9236, NI 9220)

- SR570 Low-Noise Current Preamplifier

- Tektronix TDS 5104 Oscilloscope

- Hantek DSO5202P Oscilloscope