Publications

-

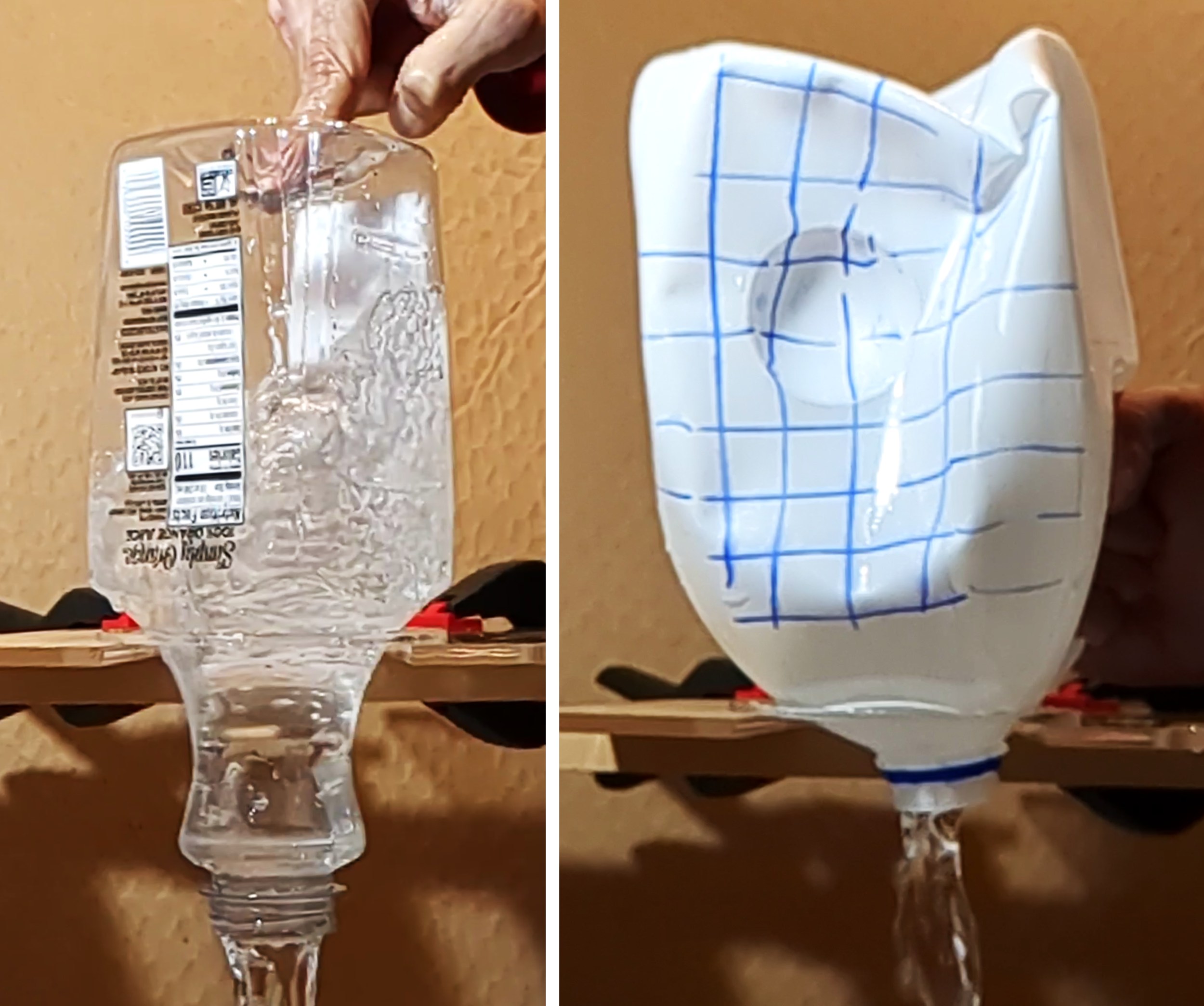

Velankar, R.S. and S.S. Velankar, Soft bottles drain faster but glug slower. Physics of Fluids, 2024. 36(9). doi: 10.1063/5.0217553

Velankar, R.S. and S.S. Velankar, Soft bottles drain faster but glug slower. Physics of Fluids, 2024. 36(9). doi: 10.1063/5.0217553 -

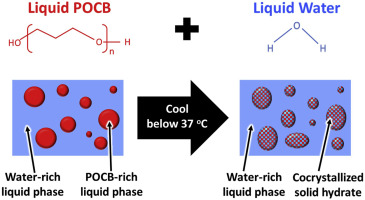

Filonowich, D., S. Velankar, and J.A. Keith, The fascinating world of polymer crystal hydrates: An overview. Aiche Journal, 2024. doi: 10.1002/aic.18556.

Filonowich, D., S. Velankar, and J.A. Keith, The fascinating world of polymer crystal hydrates: An overview. Aiche Journal, 2024. doi: 10.1002/aic.18556. -

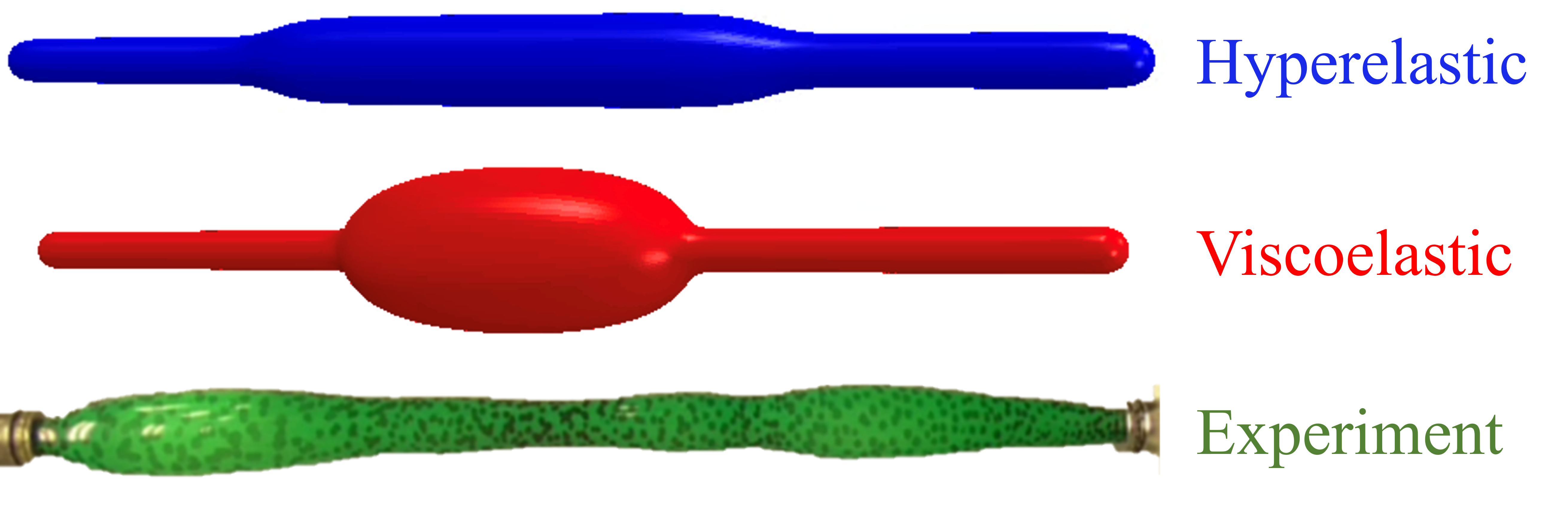

Rouhani, F., J.W. Pazin, B.A. Young, Q.H. Liu, and S.S. Velankar, Inelastic effects in bulge formation of inflated polymer tubes. Soft Matter, 2024. 20(20): p. 4152-4164. doi: 10.1039/d4sm00241e

Rouhani, F., J.W. Pazin, B.A. Young, Q.H. Liu, and S.S. Velankar, Inelastic effects in bulge formation of inflated polymer tubes. Soft Matter, 2024. 20(20): p. 4152-4164. doi: 10.1039/d4sm00241e -

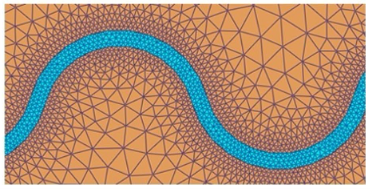

Chaudhary, S., S.S. Velankar, and C.M. Schroeder, Dynamics of meniscus-bound particle clusters in extensional flow. Journal of Rheology, 2024. 68(3): p. 397-413. doi: 10.1122/8.0000805

Chaudhary, S., S.S. Velankar, and C.M. Schroeder, Dynamics of meniscus-bound particle clusters in extensional flow. Journal of Rheology, 2024. 68(3): p. 397-413. doi: 10.1122/8.0000805 -

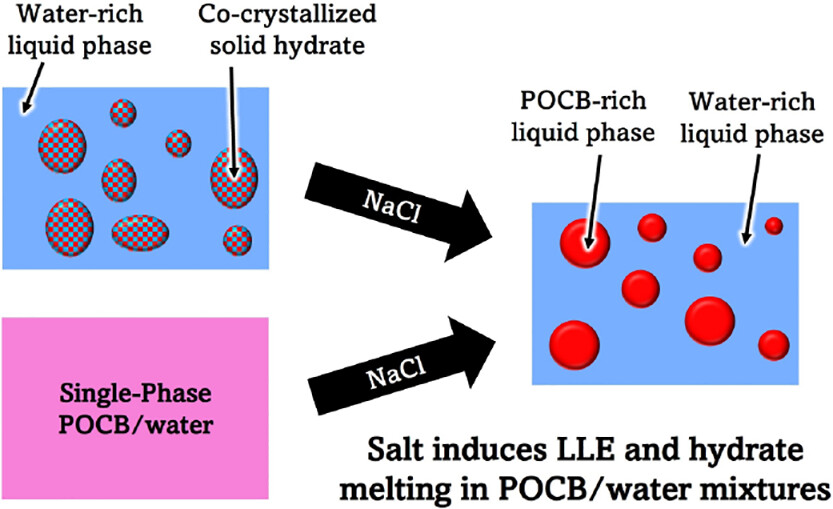

Gresh-Sill, M.; Banerjee, S.; Meyer, T. Y.; Velankar, S. S. Salt Effects on the Phase Behavior and Cocrystallization Kinetics of POCB-Water Mixtures. Langmuir 2024. doi: 10.1021/acs.langmuir.3c02428

Gresh-Sill, M.; Banerjee, S.; Meyer, T. Y.; Velankar, S. S. Salt Effects on the Phase Behavior and Cocrystallization Kinetics of POCB-Water Mixtures. Langmuir 2024. doi: 10.1021/acs.langmuir.3c02428 -

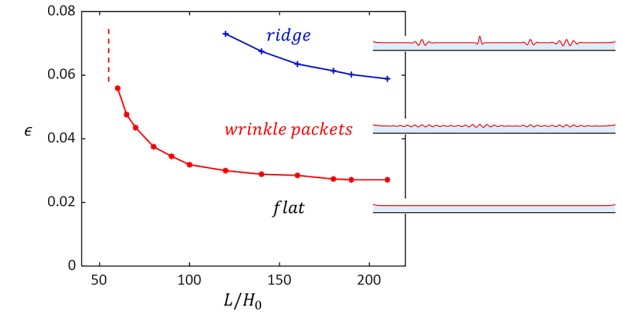

Guan, X. H.; Nguyen, N.; Cerda, E.; Pocivavsek, L.; Velankar, S. S. Ridge localization driven by wrinkle packets. Soft Matter 2023, 19 (47), 9206-9214. doi: 10.1039/d3sm01287e

Guan, X. H.; Nguyen, N.; Cerda, E.; Pocivavsek, L.; Velankar, S. S. Ridge localization driven by wrinkle packets. Soft Matter 2023, 19 (47), 9206-9214. doi: 10.1039/d3sm01287e -

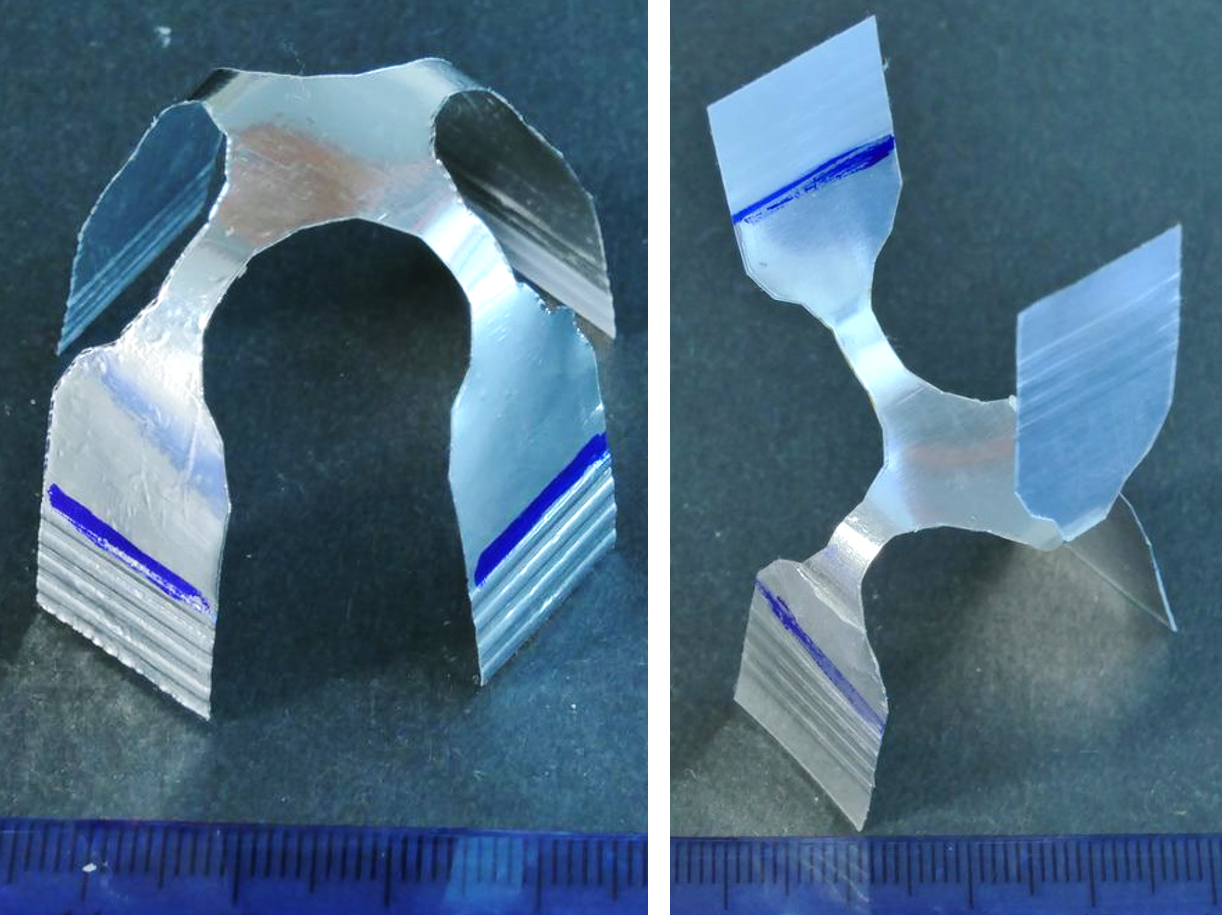

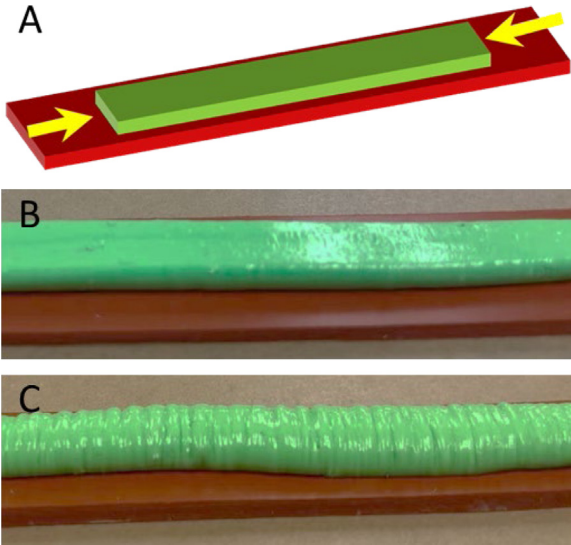

Nguyen, C.; Ramalingam, K.; Kushnir, Z.; Rouhani, F.; Velankar, S. S. Mechano-Activated Shape Morphing of Aluminum-Plastic Laminate Composites. Advanced Engineering Materials 2023. doi: 10.1002/adem.202301111

Nguyen, C.; Ramalingam, K.; Kushnir, Z.; Rouhani, F.; Velankar, S. S. Mechano-Activated Shape Morphing of Aluminum-Plastic Laminate Composites. Advanced Engineering Materials 2023. doi: 10.1002/adem.202301111 -

Banerjee, S.; Gresh-Sill, M.; Barker, E. F.; Meyer, T. Y.; Velankar, S. S. Polymer co-crystallization from LLE: Crystallization kinetics of POCB hydrate from two-phase mixtures of POCB and water. Polymer 2023, 282. doi: 10.1016/j.polymer.2023.126087.

Banerjee, S.; Gresh-Sill, M.; Barker, E. F.; Meyer, T. Y.; Velankar, S. S. Polymer co-crystallization from LLE: Crystallization kinetics of POCB hydrate from two-phase mixtures of POCB and water. Polymer 2023, 282. doi: 10.1016/j.polymer.2023.126087. -

X. Guan, N. Nguyen, L. Pocivavsek, E. Cerda, S.S. Velankar, “Flat, wrinkled, or ridged: Relaxation of an elastic film on a viscous substrate undergoing continuous compression”, International Journal of Solids and Structures, 275, 112242, 2023 doi: 10.1016/j.ijsolstr.2023.112242

X. Guan, N. Nguyen, L. Pocivavsek, E. Cerda, S.S. Velankar, “Flat, wrinkled, or ridged: Relaxation of an elastic film on a viscous substrate undergoing continuous compression”, International Journal of Solids and Structures, 275, 112242, 2023 doi: 10.1016/j.ijsolstr.2023.112242 -

N.N. Pitre, J.B. Moses, E. Tzeng, S. Abramowitch, S.S. Velankar “Crimped fiber composites: Mechanics of a finite-length crimped fiber embedded in a soft matrix”, Biomechanics and Modeling in Mechanobiology, volume 22, 1083–1094 2023 doi: 10.1007/s10237-023-01702-9

N.N. Pitre, J.B. Moses, E. Tzeng, S. Abramowitch, S.S. Velankar “Crimped fiber composites: Mechanics of a finite-length crimped fiber embedded in a soft matrix”, Biomechanics and Modeling in Mechanobiology, volume 22, 1083–1094 2023 doi: 10.1007/s10237-023-01702-9 -

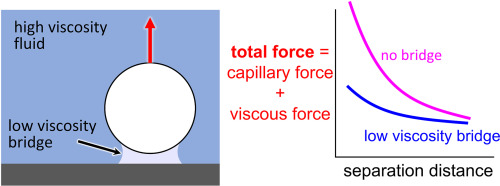

R. Lopez, J. Vasvani, J.J. McCarthy, S.S. Velankar, “Low viscosity liquid bridges: Stretching of liquid bridges immersed in a higher viscosity liquid”, Journal of Colloid and Interface Science OPEN, 9, 100079, 2023 doi: 10.1016/j.jciso.2023.100079

R. Lopez, J. Vasvani, J.J. McCarthy, S.S. Velankar, “Low viscosity liquid bridges: Stretching of liquid bridges immersed in a higher viscosity liquid”, Journal of Colloid and Interface Science OPEN, 9, 100079, 2023 doi: 10.1016/j.jciso.2023.100079 -

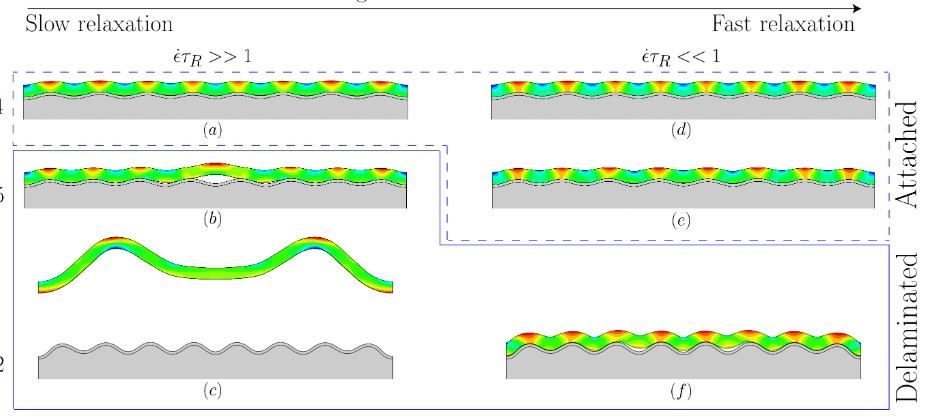

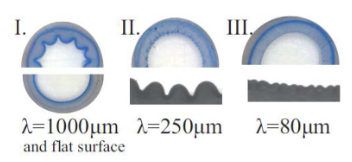

N. Nguyen, N. Nath, L. Deseri, E. Tzeng, S.S. Velankar, L. Pocivavsek, “Topographic de-adhesion in the viscoelastic limit” Journal of the Royal Society Interface, 20, 20220598, 2023 doi: 10.1098/rsif.2022.0598

N. Nguyen, N. Nath, L. Deseri, E. Tzeng, S.S. Velankar, L. Pocivavsek, “Topographic de-adhesion in the viscoelastic limit” Journal of the Royal Society Interface, 20, 20220598, 2023 doi: 10.1098/rsif.2022.0598 -

X. Guan, A.P. SarmaU, E. Kakarla HameshU, J. Yang, N. Nguyen, L. Pocivavsek, E. Cerda, S.S. Velankar, “Compression-induced buckling of thin films bonded to viscous substrates: Uniform wrinkles vs localized ridges”, International Journal of Solids and Structures, 254–255, Article 111843, 2022, doi: 10.1016/j.ijsolstr.2022.111843

X. Guan, A.P. SarmaU, E. Kakarla HameshU, J. Yang, N. Nguyen, L. Pocivavsek, E. Cerda, S.S. Velankar, “Compression-induced buckling of thin films bonded to viscous substrates: Uniform wrinkles vs localized ridges”, International Journal of Solids and Structures, 254–255, Article 111843, 2022, doi: 10.1016/j.ijsolstr.2022.111843 -

Barker, E.F., Banerjee, S., Meyer, T.Y., & Velankar, S. (2022). Liquids that Freeze when Mixed: Homogeneous Cocrystallization Kinetics of Polyoxacyclobutane-Water Hydrate. ACS APPLIED POLYMER MATERIALS, 4(1), 703-713.American Chemical Society (ACS). doi: 10.1021/acsapm.1c01626.

Barker, E.F., Banerjee, S., Meyer, T.Y., & Velankar, S. (2022). Liquids that Freeze when Mixed: Homogeneous Cocrystallization Kinetics of Polyoxacyclobutane-Water Hydrate. ACS APPLIED POLYMER MATERIALS, 4(1), 703-713.American Chemical Society (ACS). doi: 10.1021/acsapm.1c01626. -

Guan, X., Reddipalli, L., Butler, D.T., Liu, Q., & Velankar, S.S. (2022). Rate-dependent creasing of a viscoelastic liquid. EXTREME MECHANICS LETTERS, 55, 101784.. doi: 10.1016/j.eml.2022.101784.

Guan, X., Reddipalli, L., Butler, D.T., Liu, Q., & Velankar, S.S. (2022). Rate-dependent creasing of a viscoelastic liquid. EXTREME MECHANICS LETTERS, 55, 101784.. doi: 10.1016/j.eml.2022.101784. -

Breid, D., Lai, V., Flowers, A.T., Guan, X., Liu, Q., & Velankar, S.S. (2021). Drop Spreading and Confinement in Swelling-Driven Folding of Thin Films. LANGMUIR, 37(23), 6985-6994. doi: 10.1021/acs.langmuir.1c00520.

Breid, D., Lai, V., Flowers, A.T., Guan, X., Liu, Q., & Velankar, S.S. (2021). Drop Spreading and Confinement in Swelling-Driven Folding of Thin Films. LANGMUIR, 37(23), 6985-6994. doi: 10.1021/acs.langmuir.1c00520. -

Dilly, A.K., Honick, B.D., Frederick, R., Elapavaluru, A., Velankar, S., Makala, H., Hitchens, T.K., Foley, L.M., Guo, J., Beumer, J.H., Rigatti, L.H., Lee, Y.J., Bartlett, D.L., & Choudry, H.A. (2021). Improved chemosensitivity following mucolytic therapy in patient-derived models of mucinous appendix cancer. TRANSLATIONAL RESEARCH, 229, 100-114. doi: 10.1016/j.trsl.2020.10.005.

-

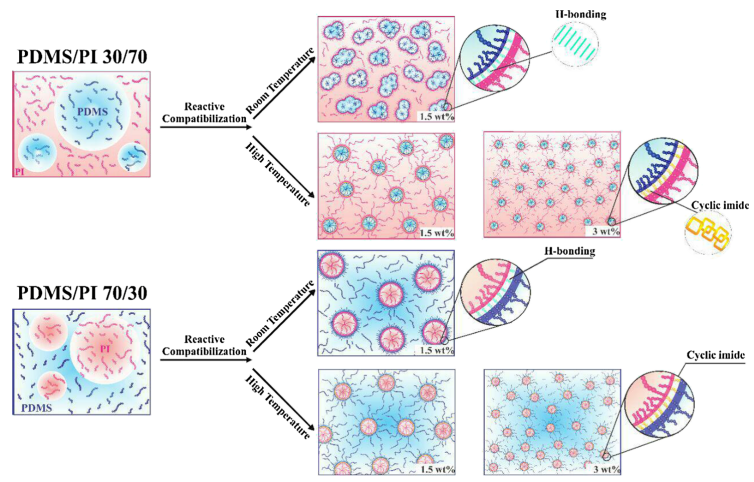

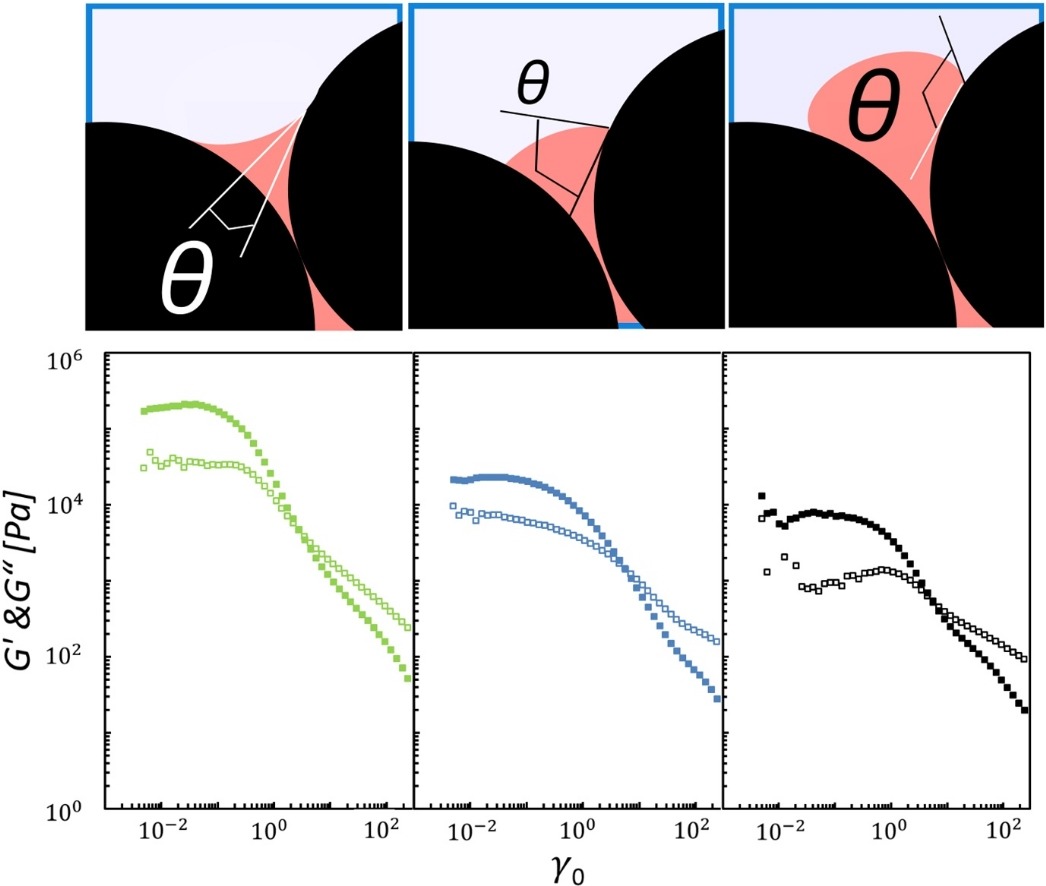

Gavgani, J.N., Goharpey, F., & Velankar, S. (2021). Interfacially compatibilized PI/PDMS blends with reduced octadecylamine-functionalized graphene oxide: morphological and rheological properties. SOFT MATTER, 17(42), 9670-9681. doi: 10.1039/d1sm01057c.

Gavgani, J.N., Goharpey, F., & Velankar, S. (2021). Interfacially compatibilized PI/PDMS blends with reduced octadecylamine-functionalized graphene oxide: morphological and rheological properties. SOFT MATTER, 17(42), 9670-9681. doi: 10.1039/d1sm01057c. -

Ramachandran, G.R., de Cortie, J., Maiti, S., Deseri, L., & Velankar, S.S. (2021). Uniaxial stretch-release of rubber-plastic bilayers: Strain-dependent transition to stable helices, rolls, saddles, and tubes. EXTREME MECHANICS LETTERS, 48, 101384.doi: 10.1016/j.eml.2021.101384.

Ramachandran, G.R., de Cortie, J., Maiti, S., Deseri, L., & Velankar, S.S. (2021). Uniaxial stretch-release of rubber-plastic bilayers: Strain-dependent transition to stable helices, rolls, saddles, and tubes. EXTREME MECHANICS LETTERS, 48, 101384.doi: 10.1016/j.eml.2021.101384. -

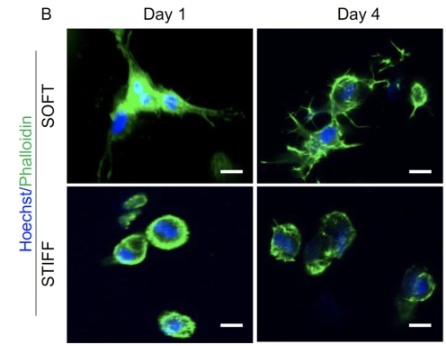

Xiang, S., Li, Z., Fritch, M.R., Li, L., Velankar, S., Liu, Y., Sohn, J., Baker, N., Lin, H., & Tuan, R.S. (2021). Caveolin-1 mediates soft scaffold-enhanced adipogenesis of human mesenchymal stem cells. STEM CELL RESEARCH & THERAPY, 12(1), 347. doi: 10.1186/s13287-021-02356-z.

Xiang, S., Li, Z., Fritch, M.R., Li, L., Velankar, S., Liu, Y., Sohn, J., Baker, N., Lin, H., & Tuan, R.S. (2021). Caveolin-1 mediates soft scaffold-enhanced adipogenesis of human mesenchymal stem cells. STEM CELL RESEARCH & THERAPY, 12(1), 347. doi: 10.1186/s13287-021-02356-z. -

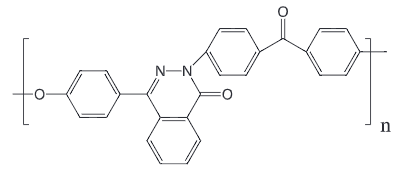

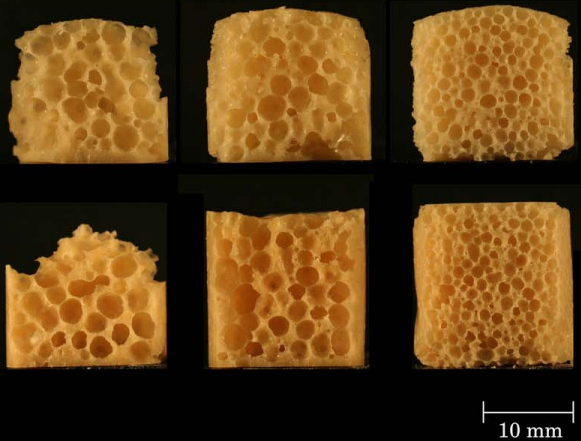

J.Y. Yang, A. Shen, and S.S. Velankar, The preparation and thermomechanical properties of high-temperature foams based on thermoplastic poly(phthalazinone ether ketone). Journal of Applied Polymer Science, 138 2021 doi: 10.1002/app.49699 Download

J.Y. Yang, A. Shen, and S.S. Velankar, The preparation and thermomechanical properties of high-temperature foams based on thermoplastic poly(phthalazinone ether ketone). Journal of Applied Polymer Science, 138 2021 doi: 10.1002/app.49699 Download -

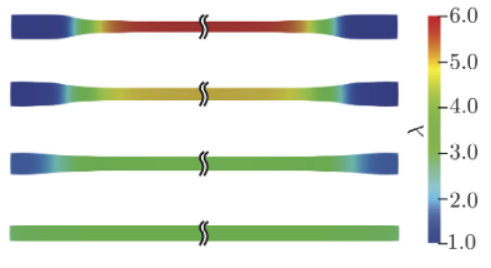

R.G. Ramachandran, S. Maiti, and S.S. Velankar, Necking and drawing of rubber-plastic laminate composites: Finite element simulations and analytical model. Journal of the Mechanics and Physics of Solids, 142 2020 doi: 10.1016/j.jmps.2020.104012 Download

R.G. Ramachandran, S. Maiti, and S.S. Velankar, Necking and drawing of rubber-plastic laminate composites: Finite element simulations and analytical model. Journal of the Mechanics and Physics of Solids, 142 2020 doi: 10.1016/j.jmps.2020.104012 Download -

A. Patel, V. Sant, S. Velankar, M. Dutta, V. Balasubramanian, P. Sane, V. Agrawal, J. Wilson, L.C. Rohan, and S. Sant, Self-assembly of multiscale anisotropic hydrogels through interfacial polyionic complexation. Journal of Biomedical Materials Research Part A, 108, 2504-2518 2020 doi: 10.1002/jbm.a.37001 Download

-

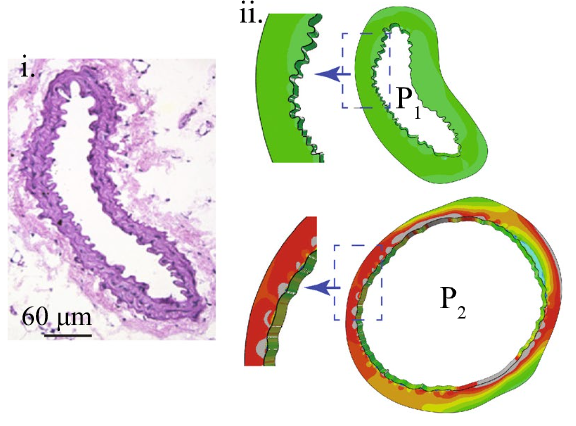

N. Nguyen, N. Nath, L. Deseri, E. Tzeng, S.S. Velankar, and L. Pocivaysek, Wrinkling instabilities for biologically relevant fiber-reinforced composite materials with a case study of Neo-Hookean/Ogden-Gasser-Holzapfel bilayer. Biomechanics and Modeling in Mechanobiology, 2020 doi: 10.1007/s10237-020-01345-0

N. Nguyen, N. Nath, L. Deseri, E. Tzeng, S.S. Velankar, and L. Pocivaysek, Wrinkling instabilities for biologically relevant fiber-reinforced composite materials with a case study of Neo-Hookean/Ogden-Gasser-Holzapfel bilayer. Biomechanics and Modeling in Mechanobiology, 2020 doi: 10.1007/s10237-020-01345-0 -

N.N. Nath, L. Pocivavsek, J.A. Pugar, Y. Gao, K. Salem, N. Pitre, R. McEnaney, S. Velankar, and E. Tzeng, Dynamic Luminal Topography: A Potential Strategy to Prevent Vascular Graft Thrombosis. Frontiers in Bioengineering and Biotechnology, 8 2020 doi: 10.3389/fbioe.2020.573400 Download

N.N. Nath, L. Pocivavsek, J.A. Pugar, Y. Gao, K. Salem, N. Pitre, R. McEnaney, S. Velankar, and E. Tzeng, Dynamic Luminal Topography: A Potential Strategy to Prevent Vascular Graft Thrombosis. Frontiers in Bioengineering and Biotechnology, 8 2020 doi: 10.3389/fbioe.2020.573400 Download -

J.D. Naranjo, L.T. Saldin, E. Sobieski, L.M. Quijano, R.C. Hill, P.G. Chan, C. Torres, J.L. Dziki, M.C. Cramer, Y.C. Lee, R. Das, A.K. Bajwa, R. Nossair, M. Klimak, L. Marchal, S. Patel, S.S. Velankar, K.C. Hansen, K. McGrath, and S.F. Badylak, Esophageal extracellular matrix hydrogel mitigates metaplastic change in a dog model of Barrett's esophagus. Science Advances, 6 2020 doi: 10.1126/sciadv.aba4526 Download

-

M. Herneisey, P.F. Salcedo, T. Domenech, C. Bagia, S.S. George, R. Tunney, S. Velankar, T.K. Hitchens, and J.M. Janjic, Design of Thermoresponsive Polyamine Cross-Linked Perfluoropolyether Hydrogels for Imaging and Delivery Applications. Acs Medicinal Chemistry Letters, 11, 2032-2040 2020 doi: 10.1021/acsmedchemlett.0c00198 Download

M. Herneisey, P.F. Salcedo, T. Domenech, C. Bagia, S.S. George, R. Tunney, S. Velankar, T.K. Hitchens, and J.M. Janjic, Design of Thermoresponsive Polyamine Cross-Linked Perfluoropolyether Hydrogels for Imaging and Delivery Applications. Acs Medicinal Chemistry Letters, 11, 2032-2040 2020 doi: 10.1021/acsmedchemlett.0c00198 Download -

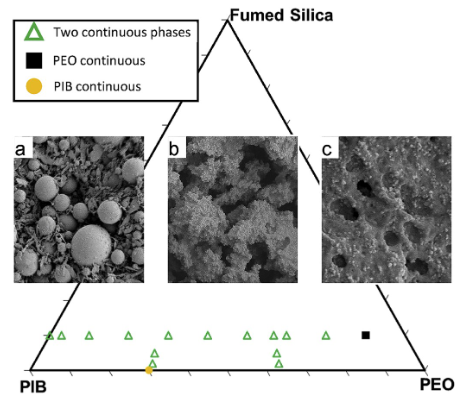

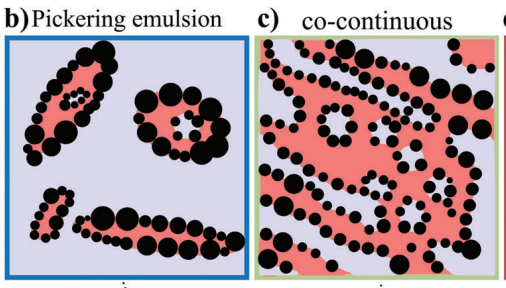

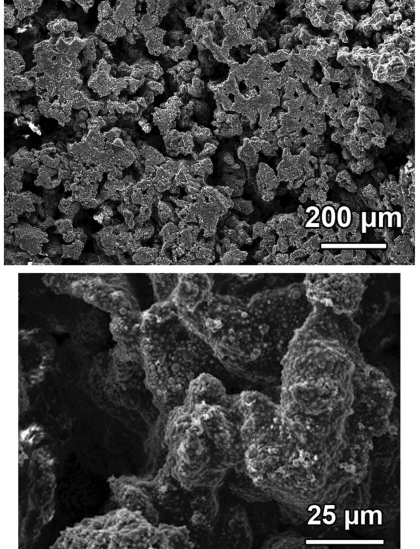

D. Amoabeng, A.J. Tempelaski, B.A. Young, B.A. Binks, S.S. Velankar, "Fumed silica induces co-continuity across a wide composition range in immiscible polymer blends", Polymer, 186, article number 121831, 2020 doi 10.1016/j.polymer.2019.121831 Download

D. Amoabeng, A.J. Tempelaski, B.A. Young, B.A. Binks, S.S. Velankar, "Fumed silica induces co-continuity across a wide composition range in immiscible polymer blends", Polymer, 186, article number 121831, 2020 doi 10.1016/j.polymer.2019.121831 Download -

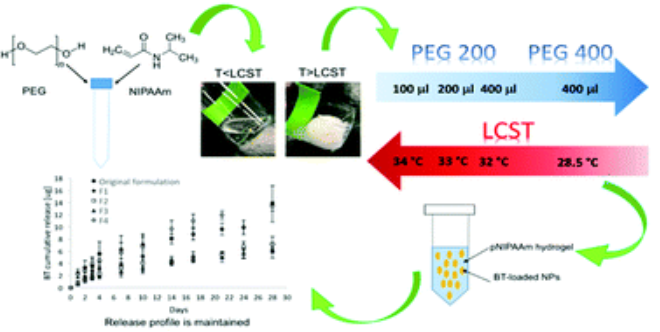

E. Bellotti, M.V. Fedorchak, S.S. Velankar, S.R. Little, “Tuning ofthermoresponsivepNIPAAm hydrogels for the topical retention of controlled release ocular therapeutics”, Journal of Materials Chemistry B, 7, 1276-1283, 2019 doi 10.1039/C8TB02976H Download

E. Bellotti, M.V. Fedorchak, S.S. Velankar, S.R. Little, “Tuning ofthermoresponsivepNIPAAm hydrogels for the topical retention of controlled release ocular therapeutics”, Journal of Materials Chemistry B, 7, 1276-1283, 2019 doi 10.1039/C8TB02976H Download -

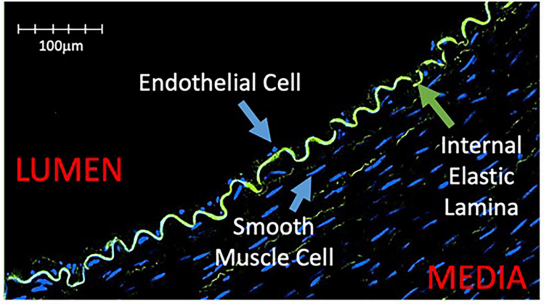

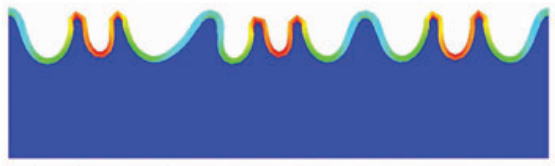

L. Pocivavsek, Sang-Ho Ye, J.Pugar, E. Cerda, E. Zheng, S.S. Velankar, W. Wagner, “Active wrinkles to drive self-cleaning: A strategy for anti-thrombotic surfaces for vascular graft”, Biomaterials, 192, 226-234, 2019doi: 10.1016/j.biomaterials.2018.11.005 Download

L. Pocivavsek, Sang-Ho Ye, J.Pugar, E. Cerda, E. Zheng, S.S. Velankar, W. Wagner, “Active wrinkles to drive self-cleaning: A strategy for anti-thrombotic surfaces for vascular graft”, Biomaterials, 192, 226-234, 2019doi: 10.1016/j.biomaterials.2018.11.005 Download -

J. Nasrollah, S.S. Velankar, R. Foudazi, F. Goharpey, “Suppressing droplet coalescence and aggregation in immiscible homopolymer blends byinterfaciallycross-linked compatibilizers”, Journal of Rheology, 62, 1217-1231, 2018 doi 10.1122/1.5020961 Download

J. Nasrollah, S.S. Velankar, R. Foudazi, F. Goharpey, “Suppressing droplet coalescence and aggregation in immiscible homopolymer blends byinterfaciallycross-linked compatibilizers”, Journal of Rheology, 62, 1217-1231, 2018 doi 10.1122/1.5020961 Download -

J. Yang, N.Heinichen, S.S. Velankar, "Effect of particle wettability on the rheology of suspensions with capillary forces", Colloids and Surfaces A, 558, 164-170, 2018doi: 10.1016/j.colsurfa.2018.08.062 Download

J. Yang, N.Heinichen, S.S. Velankar, "Effect of particle wettability on the rheology of suspensions with capillary forces", Colloids and Surfaces A, 558, 164-170, 2018doi: 10.1016/j.colsurfa.2018.08.062 Download -

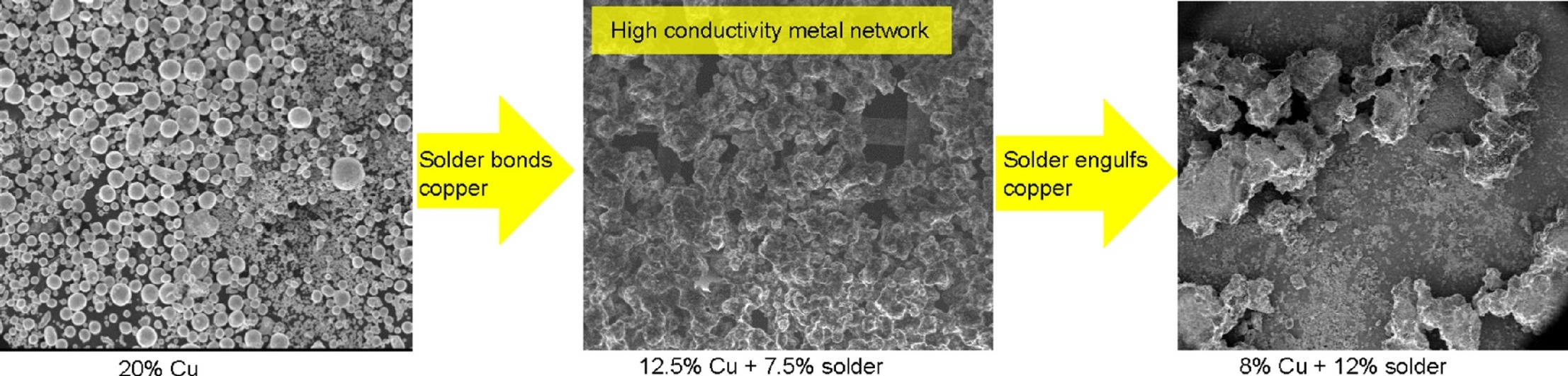

D. Amoabeng, and S.S. Velankar, “Bulk Soldering: Conductive Polymer Composites filled with copper particles and solder”, Colloids and Surfaces A, 553, 624-632, 2018.doi: 10.1016/j.colsurfa.2018.06.013Download

D. Amoabeng, and S.S. Velankar, “Bulk Soldering: Conductive Polymer Composites filled with copper particles and solder”, Colloids and Surfaces A, 553, 624-632, 2018.doi: 10.1016/j.colsurfa.2018.06.013Download -

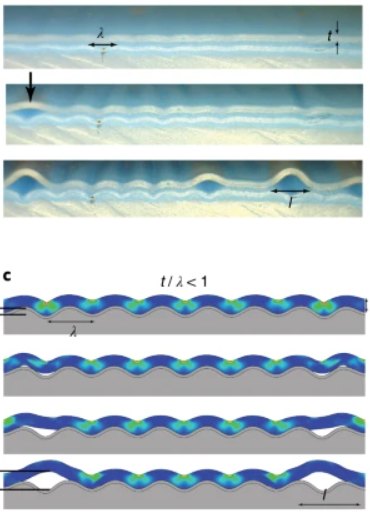

L. Pocivavsek, L., J.Pugar, R. O’Dea, S.-H. Ye, W.W. Wagner, E. Tzeng, S.S. Velankar, E. Cerda, "Topography-driven surface renewal", Nature Physics 2018Download

L. Pocivavsek, L., J.Pugar, R. O’Dea, S.-H. Ye, W.W. Wagner, E. Tzeng, S.S. Velankar, E. Cerda, "Topography-driven surface renewal", Nature Physics 2018Download -

R. Ramachandran, H. Krishnan, S.Abramowitch, S.Maiti, and S.S. Velankar, “Necking and strain hardening of multilayered plastic-rubber films”, Soft Matter, 14, 4977-4986 , 2018. doi: 10.1039/C8SM00684A Download [archived]

R. Ramachandran, H. Krishnan, S.Abramowitch, S.Maiti, and S.S. Velankar, “Necking and strain hardening of multilayered plastic-rubber films”, Soft Matter, 14, 4977-4986 , 2018. doi: 10.1039/C8SM00684A Download [archived] -

D. Amoabeng, and S.S. Velankar, “Review of improving electrical conductivity of plastics using low melting point metal alloys”, Polymer Engineering and Science, in press, doi:10.1002/pen.24774

-

M.T.Chido, P.Koronaios, K. Saravanan, A.P. Adams, S.J. Geib, Q. Zhu, H.B. Sunkara, S.S. Velankar, R.M. Enick, J.A. Keith, A. Star, “Polymer Hydrate Crystallization Improves Carbon Nanotube Memory”, Chemistry of Materials, 30, 3813–3818, 2018 doi: 10.1021/acs.chemmater.8b00964 Download [archived]

M.T.Chido, P.Koronaios, K. Saravanan, A.P. Adams, S.J. Geib, Q. Zhu, H.B. Sunkara, S.S. Velankar, R.M. Enick, J.A. Keith, A. Star, “Polymer Hydrate Crystallization Improves Carbon Nanotube Memory”, Chemistry of Materials, 30, 3813–3818, 2018 doi: 10.1021/acs.chemmater.8b00964 Download [archived] -

J. Banerjee, P.Koronaios, B.Morganstein, S.J.Geib, R.M. Enick, J.A. Keith, E.J. Beckman, S.S.Velankar, "Liquids That Freeze When Mixed: Cocrystallization and Liquid-Liquid Equilibrium in Polyoxacyclobutane-Water Mixtures", Macromolecules, 51, 3176-3183, 2018. Download [archived]

J. Banerjee, P.Koronaios, B.Morganstein, S.J.Geib, R.M. Enick, J.A. Keith, E.J. Beckman, S.S.Velankar, "Liquids That Freeze When Mixed: Cocrystallization and Liquid-Liquid Equilibrium in Polyoxacyclobutane-Water Mixtures", Macromolecules, 51, 3176-3183, 2018. Download [archived] -

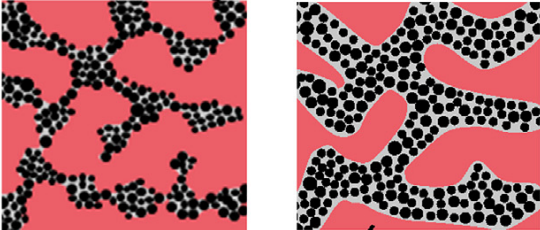

J. Yang, D.Roell, M.Echavarria, S.S. Velankar, "A structure composition map for immiscible polymer blends with partially-wetting particles", Soft Matter, 45, 8579-8589, 2017. Download [archived]

J. Yang, D.Roell, M.Echavarria, S.S. Velankar, "A structure composition map for immiscible polymer blends with partially-wetting particles", Soft Matter, 45, 8579-8589, 2017. Download [archived] -

D. Amoabeng, D.Roell, K.M. Clouse, B.A. Young, S.S. Velankar, "A composition-morphology map for particle-filled blends of immiscible thermoplastic polymers", Polymer, 119, 212-223, 2017.Download [archived]

D. Amoabeng, D.Roell, K.M. Clouse, B.A. Young, S.S. Velankar, "A composition-morphology map for particle-filled blends of immiscible thermoplastic polymers", Polymer, 119, 212-223, 2017.Download [archived] -

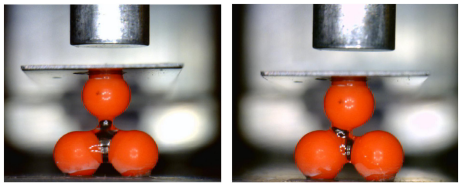

D.Lievano, S. Velankar, J.J. McCarthy, "The rupture force of liquid bridges in two and three particle systems", Powder Technology, 313, 18-26, 2017.Download [archived]

D.Lievano, S. Velankar, J.J. McCarthy, "The rupture force of liquid bridges in two and three particle systems", Powder Technology, 313, 18-26, 2017.Download [archived] -

T.J. Keane, J.Dziki, A.Castelton, D.M. Faulk, V. Messerschmidt, R. Londono, J.E. Reing, S.S. Velankar, S.F. Badylak, "Preparation and characterization of a biologic scaffold and hydrogel derived from colonic mucosa", Journal of Biomedical Materials Research Part B-Applied Biomaterials, 105, 291-306, 2017. Download [archived]

-

L.T.Saldin, M.C. Cramer, S.S. Velankar, L.J. White, S.F.Badylak, "Extracellular matrix hydrogels from decellularized tissues: Structure and function", Acta Biomaterialia, 49, 1-15, 2017. Download [archived]

-

J.Y. Yang, S.S. Velankar, "Preparation and yielding behavior of pendular network suspensions", Journal of Rheology, 61, 217-228, 2017.Download [archived]

-

T. Domenech, S.S. Velankar, "Microstructure, phase inversion and yielding in immiscible polymer blends with selectively wetting silica particles", Journal of Rheology, 61, 363-377, 2017.Download [archived]

-

J.Y. Yang, S. Damle, S.Maiti, S.S. Velankar, "Stretching-induced wrinkling in plastic-rubber composites", Soft Matter, 13, 776-787, 2017.Download [archived]

J.Y. Yang, S. Damle, S.Maiti, S.S. Velankar, "Stretching-induced wrinkling in plastic-rubber composites", Soft Matter, 13, 776-787, 2017.Download [archived] -

T.E. Domenech, J. Yang, S.J. Heidlebaugh and S.S.Velankar,”Threedistinct open-pore morphologies from a single particle-filled polymer blend”, Phys. Chem. Chem. Phys., 18, 4310-4315, 2016. Download [archived]

T.E. Domenech, J. Yang, S.J. Heidlebaugh and S.S.Velankar,”Threedistinct open-pore morphologies from a single particle-filled polymer blend”, Phys. Chem. Chem. Phys., 18, 4310-4315, 2016. Download [archived] -

J. Lobos, and S.S. Velankar, “Stabilizing polylactic acid foams byinterfacially-adsorbed particles”,Polym. Eng. Sci, 56, 9-17, 2016. doi: 10.1002/pen.24185 Download [archived]

J. Lobos, and S.S. Velankar, “Stabilizing polylactic acid foams byinterfacially-adsorbed particles”,Polym. Eng. Sci, 56, 9-17, 2016. doi: 10.1002/pen.24185 Download [archived] -

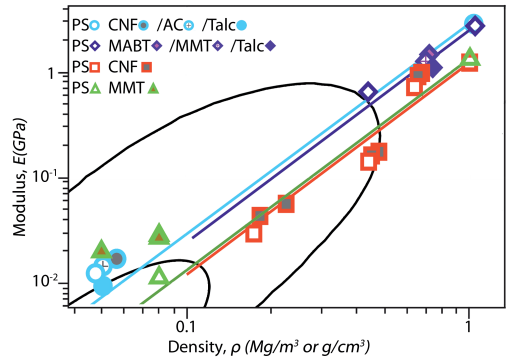

Lobos, J. and Velankar, S.S., “How much do nanoparticle fillers improve the strength and modulus of polymer foams”, J CellPlast, 52, 57-88, 2016.doi: 10.1177/0021955X14546015 Download [archived]

Lobos, J. and Velankar, S.S., “How much do nanoparticle fillers improve the strength and modulus of polymer foams”, J CellPlast, 52, 57-88, 2016.doi: 10.1177/0021955X14546015 Download [archived] -

A.R.Massensini, H.Ghuman, L.T. Saldin, C.J. Medberry, T.J. Keane, F.J. Nicholls, S.S. Velankar, S.F. Badylak, M.M. Modo, “Concentration-dependent rheological properties of ECM hydrogel for intracerebral delivery to a stroke cavity”, Acta Biomaterialia, 26, 116-130, 2015.Download [archived]

-

A. Kulkarni, A.K. Lele, S.Sivaram, P.R.Rajamohan, S.S. Velankar, A. Chatterji, “ Star-telechelic poly(l-lactide) ionomers”, Macromolecules, 48, 6580-6588, 2015.Download [archived]

-

S.S. Velankar, “A non-equilibrium state diagram for liquid/fluid/particle mixtures”, Soft Matter, 11, 8393-8403, 2015.Download [archived]

-

Z. Cai, D.H. Kwak, DPunihaole, Z. Hong, S.S. Velankar, X. Liu, and S.A. Asher, “A photonic crystal hydrogel sensor for Candida Albicans”,Angew. Chemie. Int. Ed., 53, 13036-13040, 2015. Download [archived]

-

S. Chatterjee and S.S. Velankar, “SMA-elastomer composites for reversibly-morphing surfaces”, Journal of Intelligent Material Systems and Structures, 26, 324-339, 2015.Download [archived]

-

Domenech, T.E. and Velankar, S.S., “On the rheology of pendular gels and morphological development in paste-like ternary systems based on capillary attraction”, submitted to Soft Matter, 11, 1500-1516, 2015.Download [archived]

-

S. Chatterjee, C.L. McDonald, J.Niu, S.S. Velankar, P. Wang, and R. Huang “Wrinkling and folding of thin films by viscous stress, Soft Matter, 2015, in press.Download [archived]

-

Domenech, T.E. and Velankar, S.S., “Capillary-driven percolating networks in ternary blends of immiscible polymers and silica particles”,RheolActa, 53, 1-13, 2014. Download [archived]

-

Allen, J. J., Bell, G. R. R.,Kuzirian, A. M., Velankar, S. S., Hanlon, R. T., “Comparative morphology of changeable skin papillae in octopus and cuttlefish”, Journal of Morphology, 2014, in press.Download [archived]

-

S.J.Heidlebaugh ,T. Domenech, S.V. Iasella, S.S. Velankar, “Aggregation and separation in ternary Particle/Oil/Water systems with fully wettable particles”, Langmuir, 30, 63-74, 2014. Download [archived]

-

S-C. Peng, S.P.Nagarkar, J.Lowen, S.S. Velankar, “A circuit model for the pressure-controlled generation of bubbles in a microfluidic device”, Microfluidics and Nanofluidics, 15, 797-805, 2013. Download [archived]

-

S.P.Nagarkar, S.S. Velankar, “Rheology and morphology of model immiscible polymer blends with monodisperse spherical particles at the interface”, Journal of Rheology, 57, 901-926, 2013.Download [archived]

-

Medberry, C. J.; Crapo, P. M.; Siu, B. F.; Carruthers, C. A.; Wolf, M. T.;Nagarkar, S. P.; Agrawal, V.; Jones, K. E.; Kelly, J.; Johnson, S. A.; Velankar, S. S.; Watkins, S. C.; Badylak, S. F. "Hydrogels Derived from Central Nervous System Extracellular Matrix", Biomaterials, 34, 1033-1040, 2013. Download [archived]

-

J-T. Zhang, L. Wang, X. Chao, S.S. Velankar, Sanford A. Asher, “Vertical spreading of two-dimensional crystalline colloidal arrays”, Journal of Materials Chemistry C, 1, 6099-6102, 2013.Download [archived]

-

M.T. Wolf, K.A. Daly, E.P. Brennan-Pierce, S.A. Johnson, C.A. Carruthers, A.D'Amore, S.P.Nagarkar, S.S. Velankar, S. F. Badylak, “A hydrogel derived from decellularized dermal extracellular matrix”, Biomaterials, 33, 7028–7038, 2012. Download [archived]

-

S.P.Nagarkarand S.S. Velankar, “Morphology and rheology of ternary fluid–fluid–solid systems”, Soft Matter, 8, 8464–8477, 2012. Download [archived]

-

J-T. Zhang, L. Wang, D.N. Lamont, S.S. Velankar, and S.A. Asher, “Fabrication of Large-Area Two-Dimensional Colloidal Crystals”,Angew. Chem. Int. Ed., 51, 6117–6120, 2012.Download [archived]

-

S.S. Velankar, V. Lai, R.A.Vaia, “Swelling-induced delamination causes folding of surface-tethered polymer gels”, ACS App. Mat. Int., 4, 24-29, 2012.Download [archived]

-

C. DeLeo, C.A.Pinotti, Maria doCarmo Gonçalves, S.S. Velankar, “Preparation and characterization of clay nanocomposites of plasticized starch and polypropylene polymer blends”, J. Polym Envir., 19, 689-697, 2011. Download [archived]

-

S. Fu, A. Thacker, D.M.Sperger, R.L.Boni, I.S. Buckner, S.S. Velankar, E.J.Munson, L.H. Block, “Relevance of Rheological Properties of Sodium Alginate in Solution to Calcium Alginate Gel Properties”, AAPS PharmSciTech, 12, 453-460, 2011. Download [archived]

-

C. DeLeo, S.S. Velankar, “Effect of composition on the rheology and morphology of reactively-compatibilized model polymer blends”, J. Rheology, 55, 713-731, 2011.Download [archived]

-

S. Fu, A. Thacker, D.M.Sperger, R.L.Boni, S.S. Velankar, E.J.Munson, L.H. Block, “Rheological Evaluation of Inter-grade and Inter-batch Variability of Sodium Alginate”, AAPS PharmSciTech, 11, 1662-1674, 2010. Download [archived]

-

P.Thareja, K. Moritz, S.S. Velankar, “The effect ofinterfacially-adsorbed particles in polymer blends: Coalescence suppression vs. coalescence promotion”, Rheol. Acta., 49, 285-298, 2010. Download [archived]

-

C. DeLeo, J. Goetz, B. Young, S.S. Velankar, “Renewable elastomers based on blends ofmaleatedpolypropylene and plasticized starch”, J. Appl. Polym. Sci. 116, 1775–1781, 2010. Download [archived]

-

J.N.Marhefka, R. Zhao, Z. Wu, S.S. Velankar, J.F.Antaki and M.V. Kameneva, “Drag reducing polymers improve tissue perfusion via modification of the RBC traffic in microvessels”, Biorheology, 46, 281-292, 2009. Download [archived]

-

M.M.Muscatello, L.E.Stunja, P. Thareja, L. Wang, J.J. Bohn, S.S. Velankar, and S.A. Asher, “Dependence of photonic crystal nanocomposite elasticity on crystalline colloidal array particle size”, Macromolecules, 42, 4403-4406, 2009. Download [archived]

-

H-L. Cheng and S.S. Velankar, “Controlled jamming of particle-laden interfaces using a Spinning Drop Tensiometer”, Langmuir, 25, 4412-4420, 2009.Download [archived]

-

C. DeLeo, S.S. Velankar, “Rheology of immiscible blends with compatibilizer: Differences betweendiblocksand reactive compatibilizers”, J. Rheology, 52, 1385-1404, 2008. Download [archived]

-

J.N.Marhefka, S.S. Velankar, T.M. Chapman, and M.V.Kameneva, “Mechanical degradation of drag reducing polymers in suspensions of blood cells and rigid particles”, Biorheology, 45, 599-609, 2008. Download [archived]

-

J.N.Marhefka, S.S. Velankar, R. Zhao, Z. Wu, J.F.Antaki, and M.V. Kameneva, “Microscale effects of drag-reducing polymers”, Biorheology, 45, 58-59, 2008.

-

P.Thareja, B.P.Ising, S.J. Kingston, S.S. Velankar, “Polymer foams stabilized by particles adsorbed at the air/polymer interface”, Macromol. Rapid Comm., 29, 1329-1334, 2008. Download [archived]

-

P.Thareja, S.S. Velankar, “Interfacial activity of particles at PI/PDMS and PI/PIB interfaces: Analysis based onGirifalco-Good theory”, Colloid Polym. Sci., 286, 1257-1264, 2008. Download [archived]

-

J. Martin, S.S. Velankar, “Unusual dynamics of PEG/PPG/Pluronic interfaces”, J. Colloid Int. Sci., 322, 669-674, 2008.

-

D.O.Freytes, J.D. Martin, S.S. Velankar, A.S. Lee, S.F.Badylak, “Preparation and characterization of an injectable form of the porcine Urinary Bladder Matrix”, Biomaterials, 29, 1630-1637, 2008. Download [archived]

-

J. Martin, S.S. Velankar, “Varying the blending protocol to control the morphology of immiscible polymer blends with compatibilizer”,AIChEJ, 54, 791-801, 2008. Download [archived]

-

P.Thareja, S.S. Velankar, Rheological effects of particle-induced bridging in PEO/PIB blends”,Rheol. Acta, 47, 189-200, 2008.

-

M. Angeles, H-L. Cheng, S.S. Velankar, “Emulsion electrospinning: Composite fibers from drop breakup during electrospinning”, Polymers for Advanced Technologies, 19, 728-733, 2008.Download [archived]

-

H-L. Cheng and S.S. Velankar, “Film-climbing of particle-laden interfaces”, Colloids and Surfaces A, 315, 275-284, 2008.Download [archived]

-

S.S. Velankar, D. Giles “How do I know my phase angles are correct?”,Rheol. Bulletin, 76 (2), 8, 2007.Download [archived]

-

J. Martin, S.S. Velankar, “Effects of Compatibilizer on Immiscible Polymer Blends near Phase Inversion”, J.Rheol., 51, 669-692, 2007.Download [archived]

-

P.Tharejaand S. Velankar, “Particle-induced bridging in immiscible polymer blends”, Rheol. Acta, 46, 405-512, 2007. Download [archived]

-

B.J.Adzimaand S. Velankar, “Pressure drops for droplet flows in microfluidic channels”, J. Micromechanics and Microeng., 16, 1504-1510, 2006. Download [archived]

-

J. Wang, S. Velankar, “Strain recovery of model immiscible blends: Effects of added compatibilizer”,Rheol. Acta, 45, 741-753, 2006.Download [archived]

-

J. Wang, S. Velankar, “Strain recovery of model immiscible blends without compatibilizer”,Rheol. Acta, 45, 297-304, 2006.Download [archived]

-

J. Martin, S. Velankar, “Interfacial Tension Errors from the Cohen and Carriere Analysis of Imbedded Fiber Retraction”, Macromolecules, 38, 10614-10618, 2005.Download [archived]

-

S. Velankar, P. VanPuyvelde, J.Mewis, P. Moldenaers, “Steady-shear rheological properties of model compatibilized blends”, J. Rheol., 48, 725-745, 2004. Download [archived]

-

E. VanHemelrijck, P. VanPuyvelde, S. Velankar, C.W. Macosko, P. Moldenaers, “Interfacial viscoelasticity and coalescence suppression in compatibilized polymer blends”, J. Rheol., 48, 143-158, 2004. Download [archived]

-

S. Velankar, H. Zhou, H.K. Jeon, C.W.Macosko, “CFD-evaluation of drop retraction methods for the measurement of interfacial tension of surfactant-laden drops”, J. Colloid Int. Sci., 272, 172-185, 2004.Download [archived]

-

P. Van Puyvelde, S. Velankar, J. Mewis, P. Moldenaers, “Effect of Marangoni stresses on the deformation and coalescence in compatibilized immiscible polymer blends”, Polym. Eng. Sci., 42, 1956-1964, 2002. Download [archived]

-

S. Velankar, P.Moldenaers, “Bidispersepolymeric mixtures for independent control of viscosity and elasticity”, Rheol. Acta, 41, 394-407, 2002. Download [archived]

-

S. Velankar, P. VanPuyvelde, J.Mewis, P. Moldenaers, “Effect of compatibilization on the breakup of polymeric drops in shear flow”, J. Rheol., 45, 1007-1019, 2001. Download [archived]

-

S. Velankar, S.L. Cooper, “Microphase separation and rheological properties of polyurethane melts. Part 3: Effect of block incompatibility on the viscoelastic properties”, Macromolecules, 33, 382-394, 2000.Download [archived]

-

S. Velankar, S.L. Cooper, “Microphase separation and rheological properties of polyurethane melts. Part 2: Effect of block incompatibility on the microstructure”, Macromolecules, 33, 395-403, 2000.Download [archived]

-

S. Velankar, S.L. Cooper, “Microphase separation and rheological properties of polyurethane melts. Part 1: Effect of block length”, Macromolecules, 31, 9181-9192, 1998.Download [archived]

-

S. Velankar, J.Pazos, S.L. Cooper, “High performance UV-curable urethane acrylates via deblocking chemistry”, J. Appl.Polym. Sci., 62, 1361-1376, 1996. Download [archived]